|

Many welders, fabricators and businesses in the met-fab industry are battling increased demand for their products while trying to maintain a consistent production level that is economically sustainable without jeopardizing quality. Are you struggling to maximize the output of your welding operations while faced with daunting challenges related to labor shortages? You are not alone!

Fortunately, there is now an innovative solution – MOD-WELD's cobot welding solution! This collaborative robotic equipment will help you boost productivity without breaking the bank or sacrificing product quality. Adopting the current technologies of your industry is vital for competitiveness- learn how APT’s MOD-WELD Cobot can help your business embrace automation and meet evolving customer demands! |

PA Regional Sales Manager, John Ciurlino, showing off the MOD-WELD at MX2023. Footage courtesy of WGAL8

|

Boost Efficiency and Productivity

Cobots empower your workforce to do more with less! Streamlined processes mean optimized labor, saving you time and money.

Top-Tier Partnerships

FANUC Intelligence

With FANUC's iRVision, Through-ARC Seam Tracking, and TouchSensing, achieve unmatched precision and efficiency.

Better Quality Product that is Quicker to Market

Experience higher productivity and quality- double your throughput with better accuracy and consistent welds.

Lifetime Support

With FANUC's "Service First" approach, you're backed by a lifetime of support and expertise.

|

Check out the MAC Series with the APT Clever Torch: even the most complex problem becomes effortlessly programmable, making precision welding a breeze. Bringing together the power of the FANUC CRX Cobot and the top-tier performance of the Fronius TPS/i or Miller Auto-Continuum (it's your choice!) to ensure a safer, more efficient result! Engineered for safe human interaction, the MAC Series ensures a secure and productive welding environment. Minimize downtime and maximize productivity with quick deployment and setup!.

|

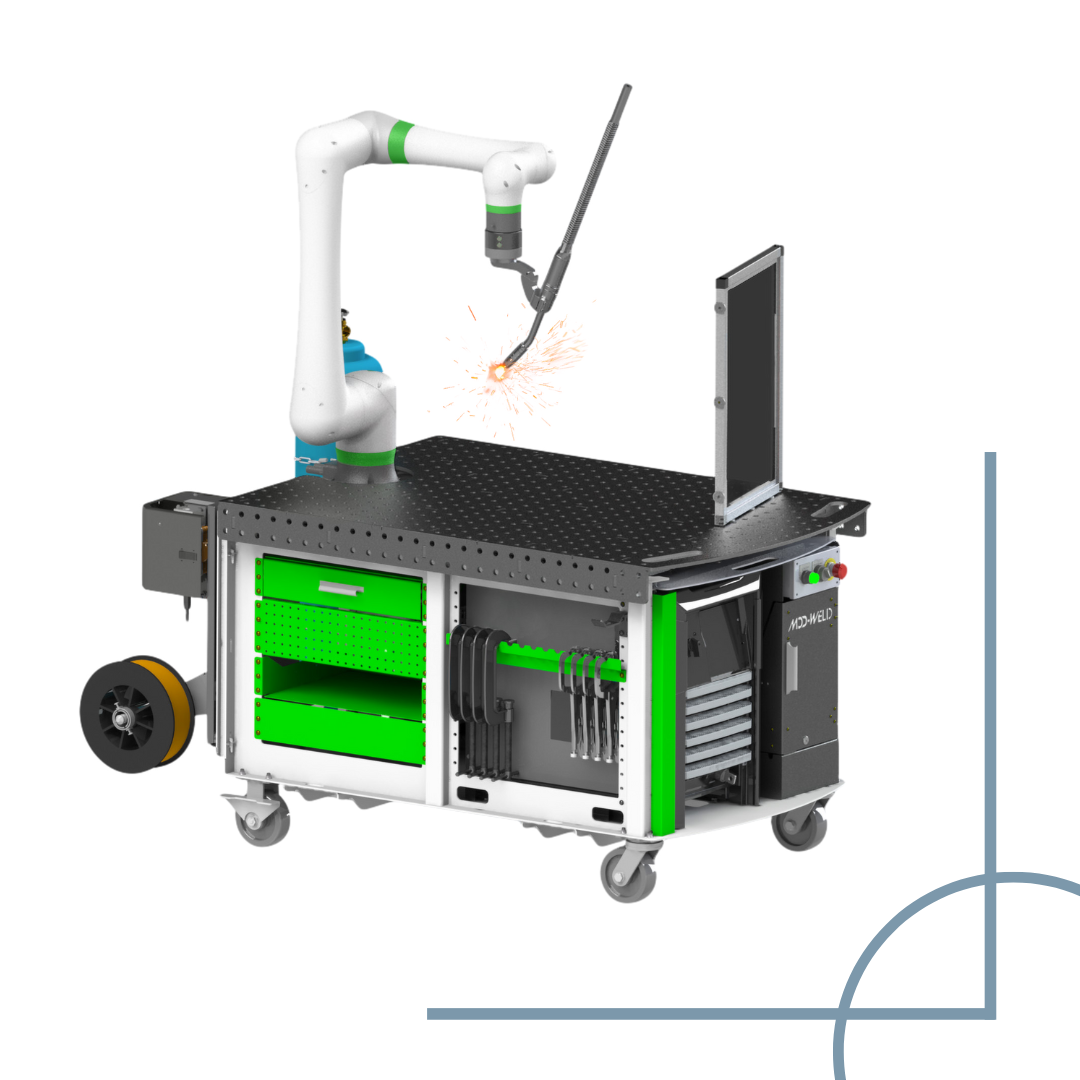

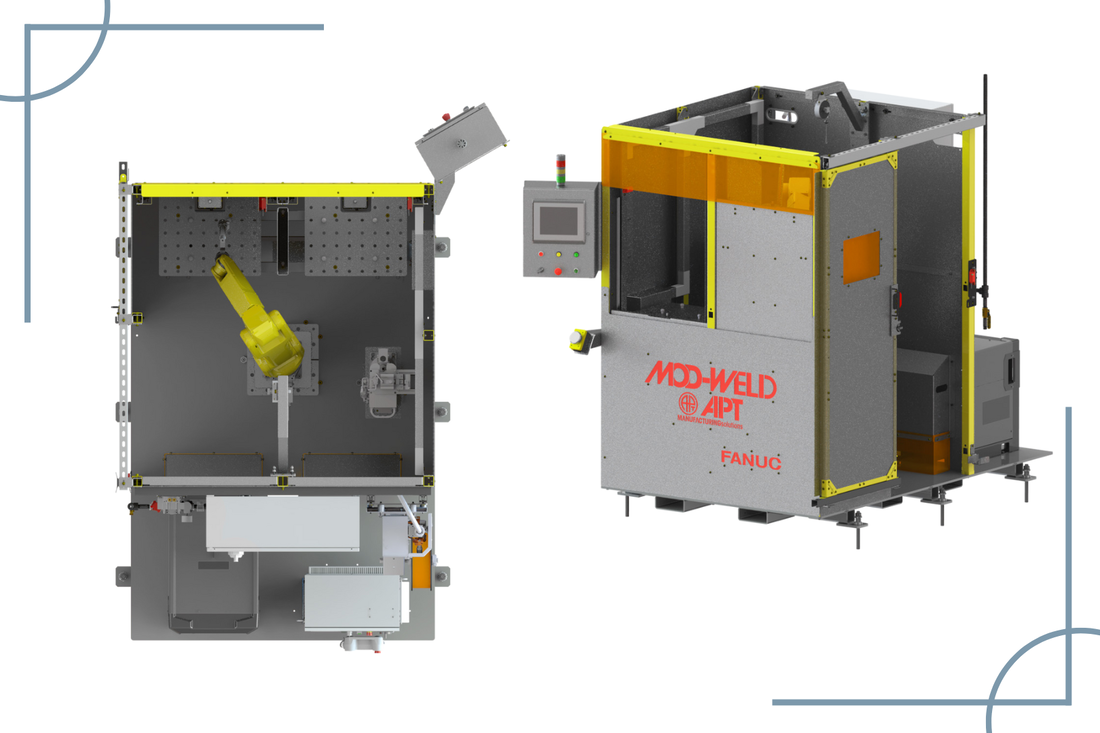

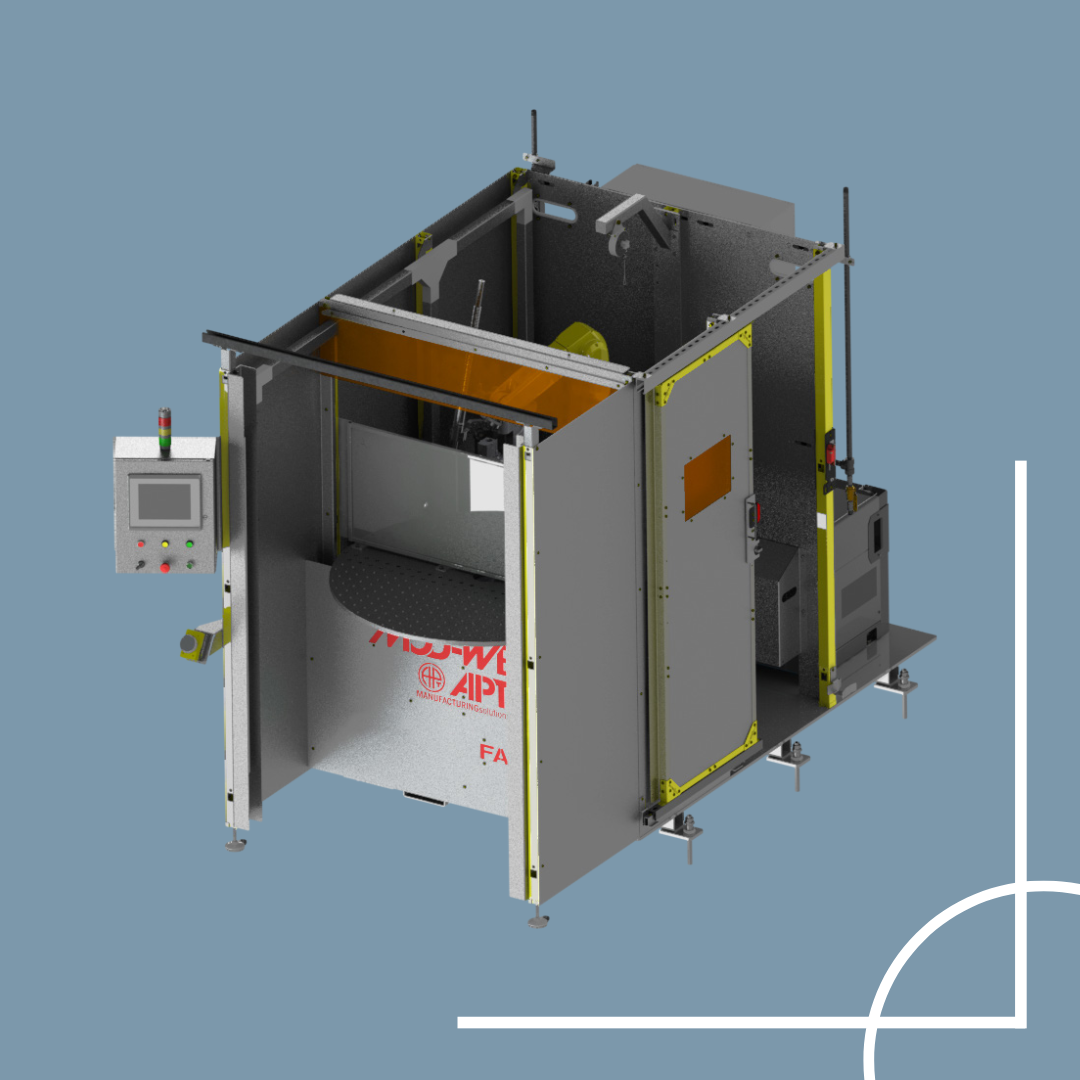

Cobot Mac CartCollaborative Robot for Arc Welding

The MOD-WELD is designed and manufactured around the FANUC CRX-10iA/L industrial collaborative robot. The CRX models come from a long line of reliable FANUC products that are extremely easy to setup, program, and operate – even if it’s your first robot. The system includes your choice of either the Fronius TSP/i or Miller Auto-Continuum. The new power source is a smart and powerful digital design, it has the fast response needed to deliver the most stable welding performance for better welding results. |

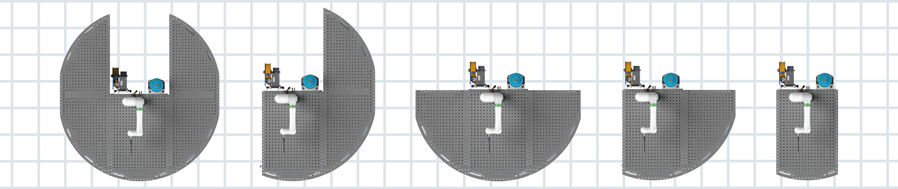

EXTENDED TABLE SPACE OPTIONS

|

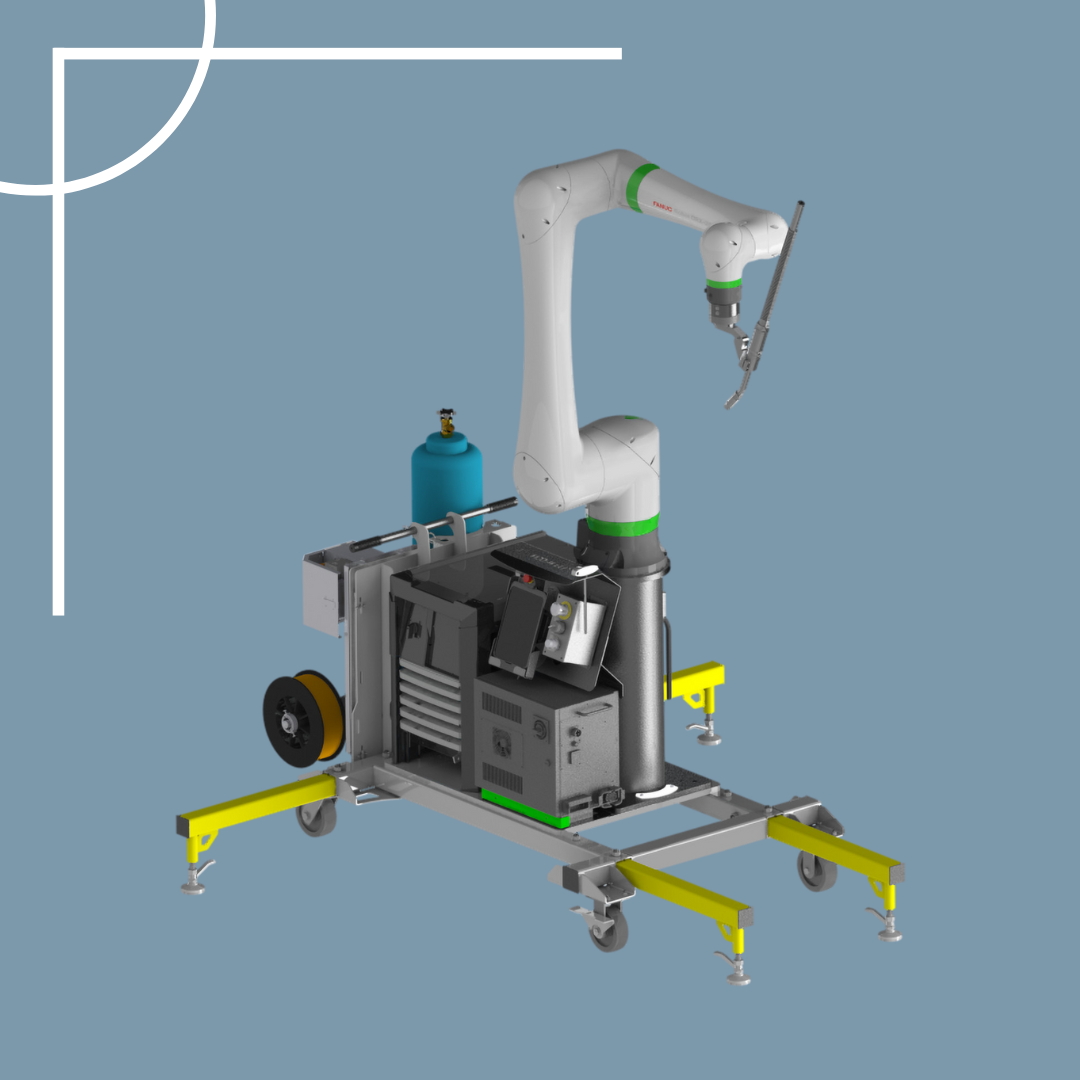

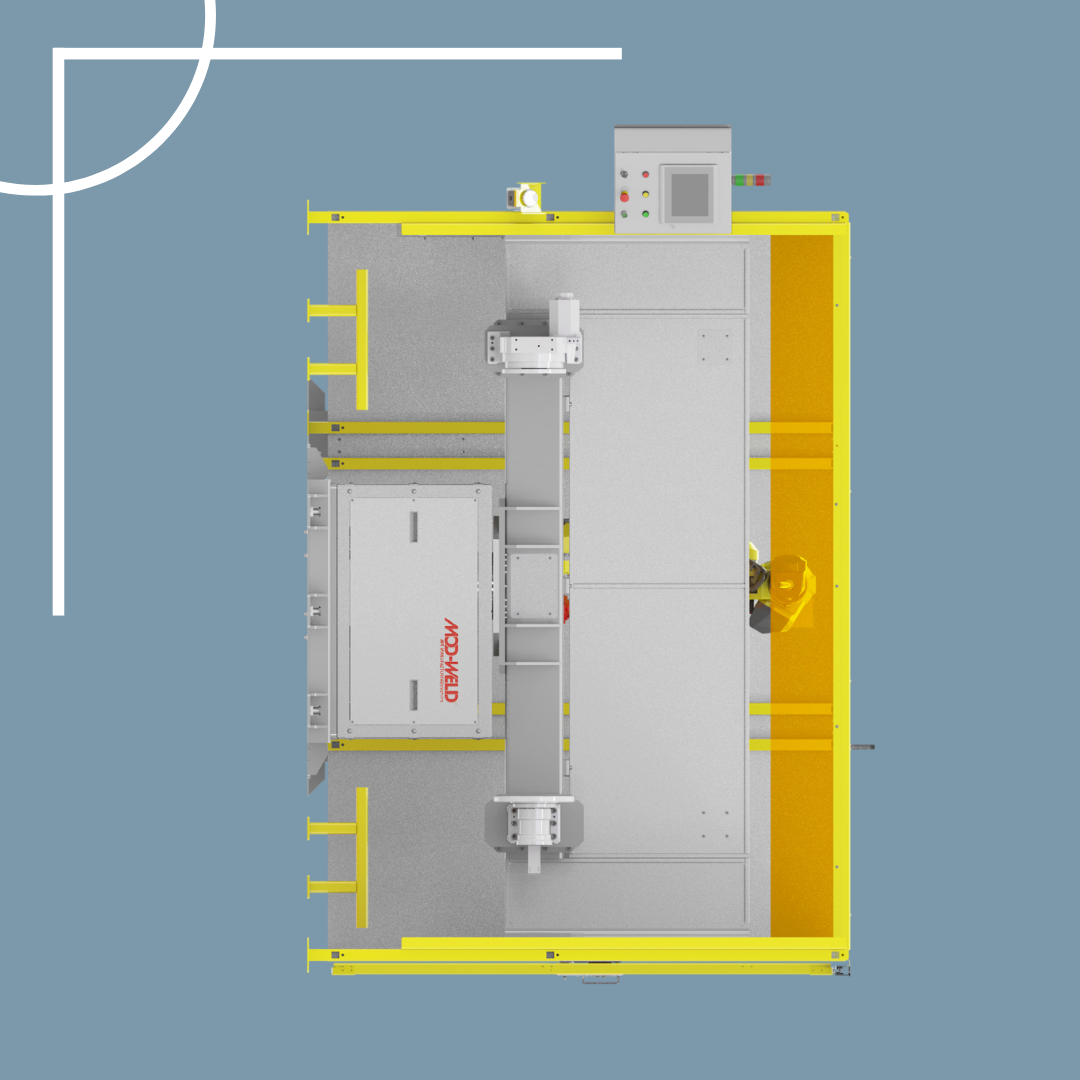

Cobot Mac TravelerCollaborative Robot for Arc Welding

A mobile welding solution designed for precision and efficiency. Just push the robot and mobile base up to the work or existing table! With welded construction, a powder coat finish, and anti-tip outriggers, it's built for stability. Equipped with your choice between Fronius TSP/i or Miller Auto-Continuum 350, plus a FANUC CRX Cobot, and APT Clever Torch software, it's ready to teach and weld with ease. The APT Clever Torch simplifies movement and teaching, even featuring a built-in tack welding button. Plus, convenient gas bottle storage on the base and 6" casters for effortless mobility make it a must-have!

|

Mac Bundle

|

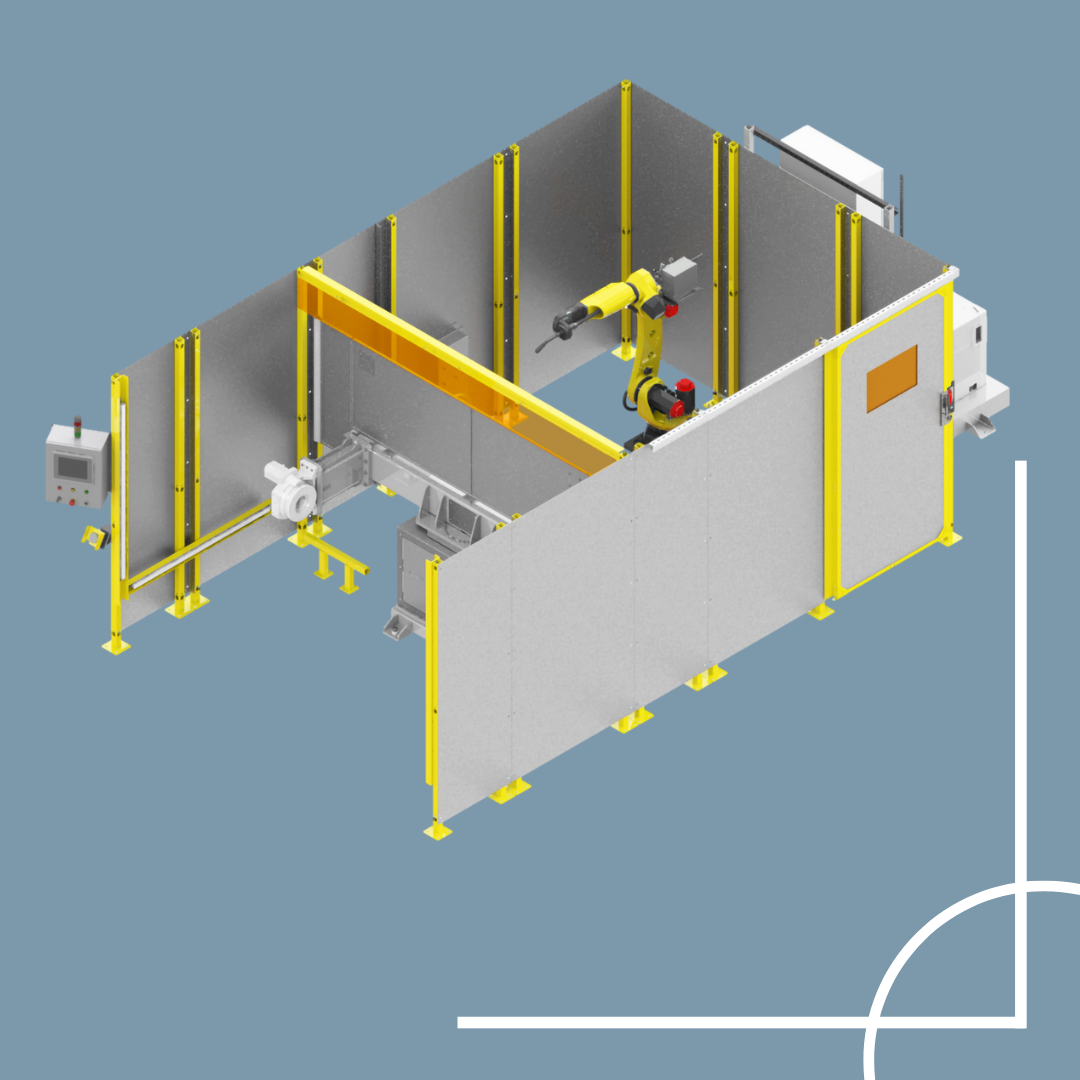

Collaborative Robot for Arc Welding

Your all-in-one welding solution! Equipped with either the Fronius TSP/i or Miller Auto-Continuum 350, plus wiredrive, MIG kit, Tregaskis Robot torch, and the FANUC CRx Collaborative Robot with APT Clever Torch software, it's ready to teach and weld. The integrated operator push button panel and user-friendly setup make it a versatile addition to any workspace.

Install it to your existing fixture table, base, or pedestal for seamless operation! |

|

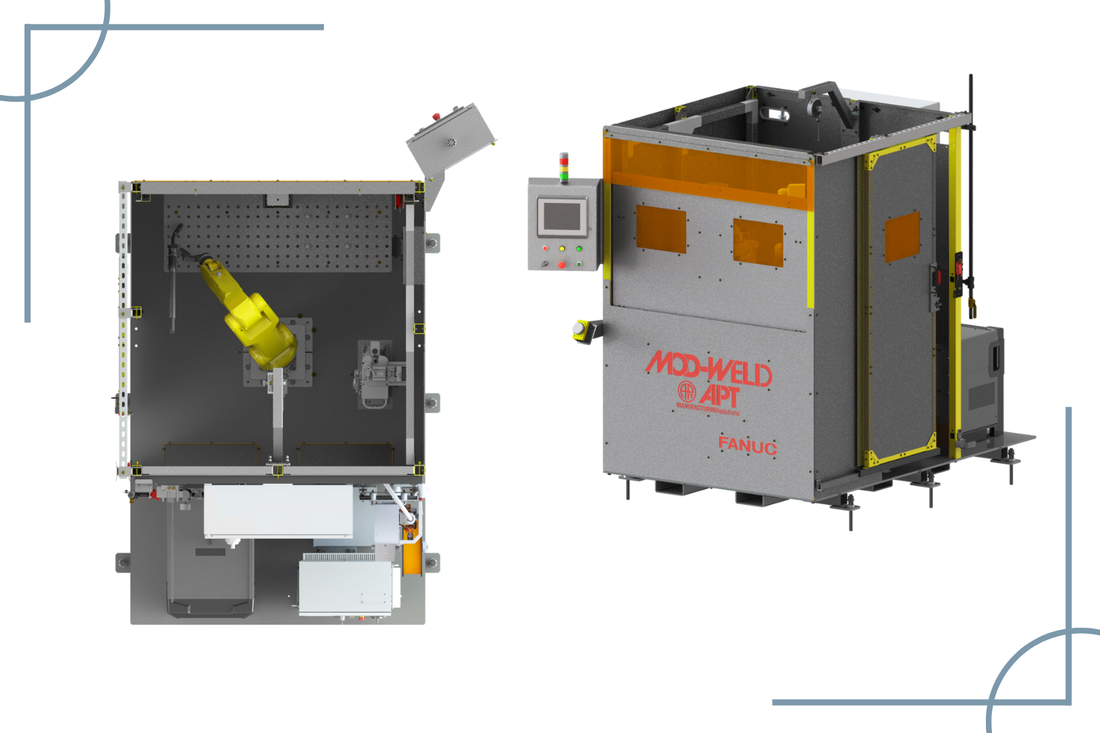

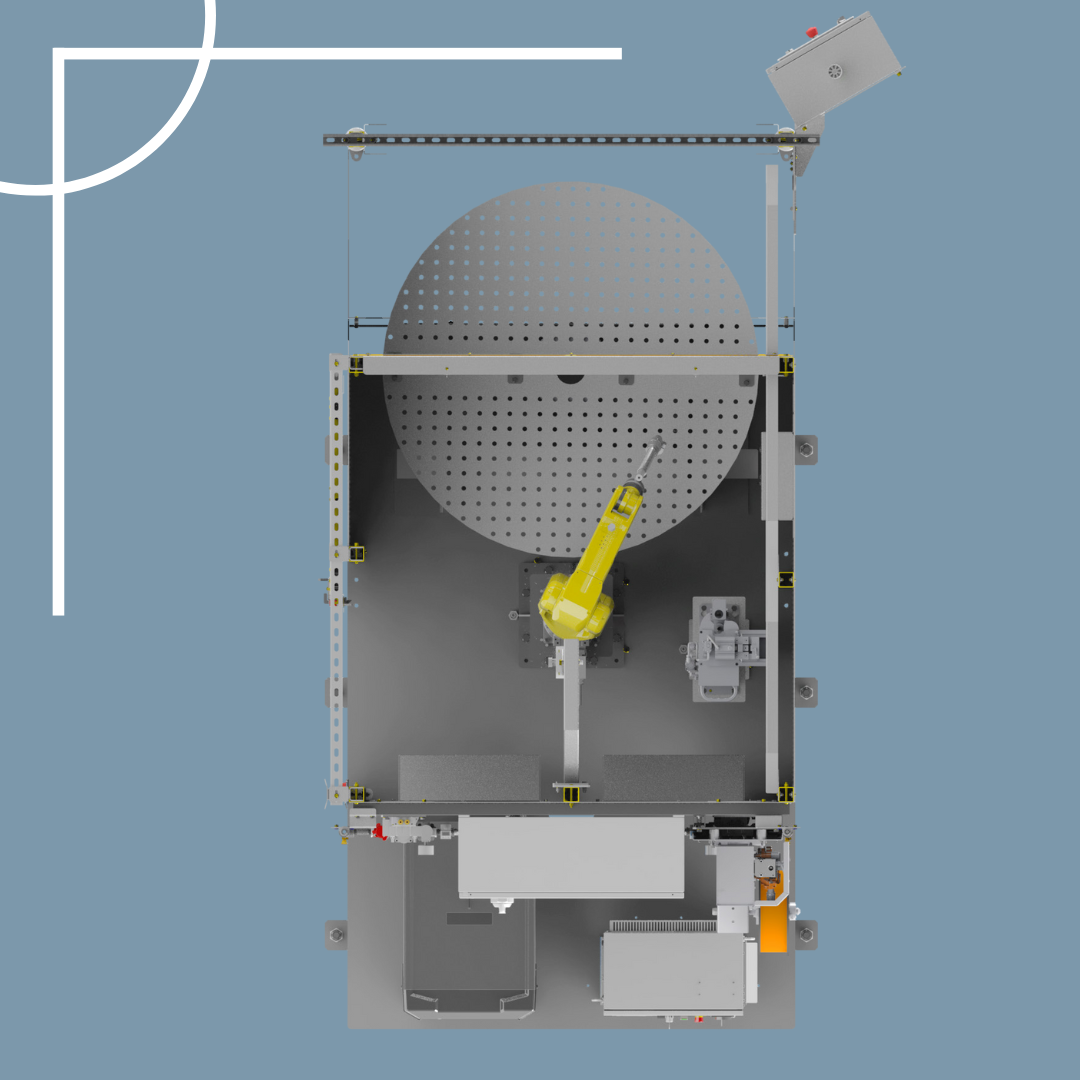

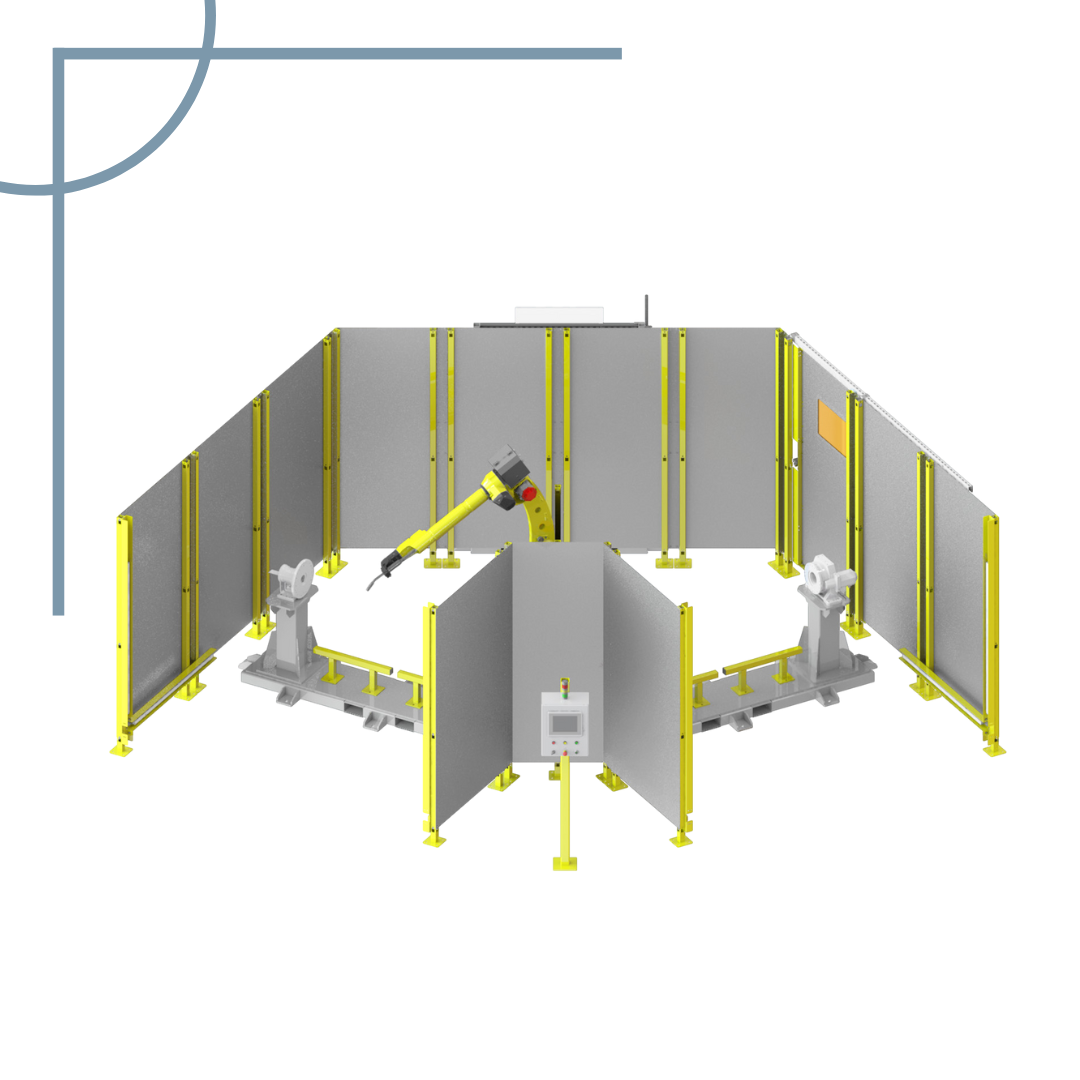

Meet the MATE Series—a game-changer in welding technology that's here to make your processes easier. With Rockwell controls at its core, the MATE Series guarantees unmatched precision and control. Efficiently handle high-volume production, optimizing your processes for maximum output! Simplicity is key, and the MATE Series understands that. With an operator interface designed for ease of use, even beginners can navigate it with confidence. Seamlessly integrates with the FANUC ARC Mate Series robot and your choice of either the Fronius TSP/i or Miller Auto-Continuum, bringing automation and precision to your welding projects. The MATE Series is primed for automated fixtures, reducing setup time and boosting overall efficiency. Perfect if you're looking for a small footprint with big capabilities!

|

Fixed Wide Table

|

|

Ready to see how APT’s MOD-WELD Cobot can help your business? Reach out today!

|

|

|