- Fronius Welding Products

- >

- Machines

- >

- Fronius TransTig 170 TIG/Stick Package

Fronius TransTig 170 TIG/Stick Package

SKU:

49,0400,0012

$2,563.00

$2,563.00

Unavailable

per item

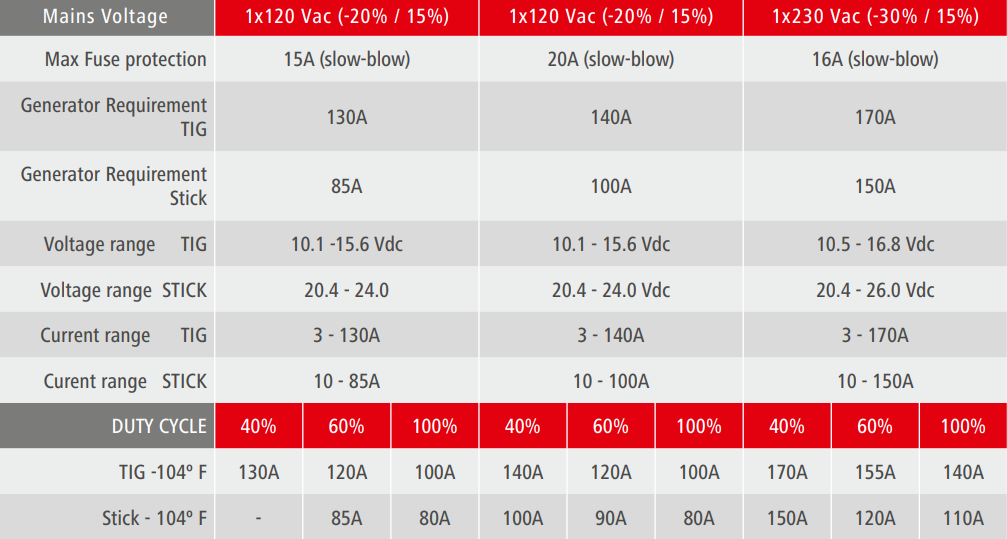

TIG/Stick Welding Machine

| |||||||||