- Fronius Welding Products

- >

- Machines

- >

- Fronius TransPocket 180

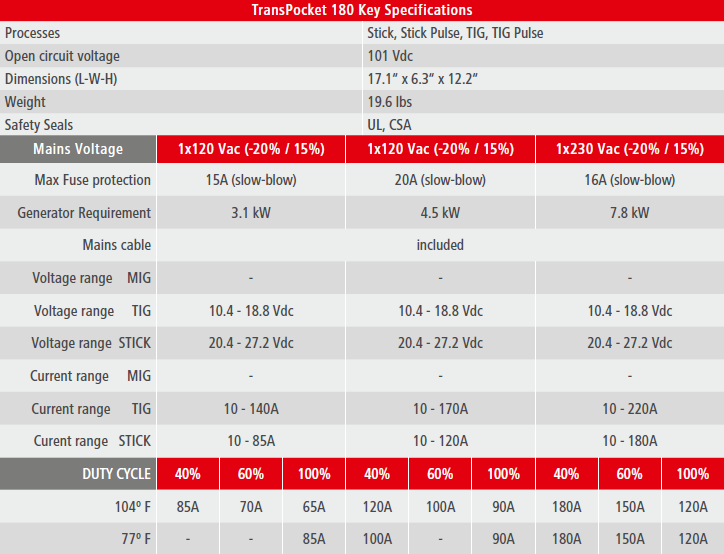

Fronius TransPocket 180

SKU:

$1,642.00

1642

2470

$1,642.00 - $2,470.00

Unavailable

per item

The TransPocket by Fronius is a Stick & TIG DC Portable Welding Machine that is extremely durable and user friendly. Shop now!

|

EASY TO USE

|

|

|

Features

Anti-Stick If a short circuit occurs that causes the electrode to stick during SMAWwelding, the power source is switched off immediately. This prevents the electrode from burning out and allows operators to remove the electrode from the work piece after making contact. Preconfigured Welding Modes The TransPocket 180 includes operating modes specficially for basic 7018 and cellulose 6010. The maximum electrode size is 5/32. Soft Start The SoftStart function ensures a stable arc at the start of welding and was specially developed for electrodes that are welded with a low welding current (basic electrodes). Hotstart To make the electrode easier to ignite, the current at the power source is increased for a fraction of a second during ignition. The HotStart function was specially developed for welding with rutile and Cel electrodes. Time ShutDown Function TSD switches off the power supply after a user specified time window, saving energy. Future Ready The new device generation is ready for future innovation. New software versions, special processes, and system information can easily be applied as it becomes available. TAC With TAC, one spot is all it takes for tacking, because the pulsed arc sets the two weld pools in motion, making them jump together in next to no time, to make one single weld-pool. The TAC function is also very useful when welding light-gauge sheets without filler metal. TIG COMFORT STOP At the end of the welding operation, the welding current is switched off automatically if a specific change is made to the arc length. This prevents the arc being unnecessarily elongated when the TIG welding torch is lifted off the workpiece to end the welding process. This results in a better weld result in the area of the end-crater, as the gas shield is maintained. Convenient wheeled storage case Digital power correction technology Dual voltage design (110 & 230) Consistent welds 300+ feet from outlet 3 years parts and labor warranty Downloads

Package options

| ||||||||||||||||||||||||||||||||||||||||||||||||