REVOLUTIONARY LASER TECHNOLOGY FOR WELDIng

|

The FIRST Truly Portable Laser Welding and Cleaning System | This innovative system uses fiber optics to deliver a beam powerful enough to weld most metals, taking your welding game to the next level! It offers a more efficient, faster process with more aesthetically pleasing results when compared to traditional MIG or TIG. Set up is a breeze- the intuitive controls with built-in factory presets allow new welders to learn within hours!

LightWELD offers three different options- LightWELD, LightWELD XC, and LightWELD XR so there's a solution for every application! |

|

Here are some of LightWELD's unique features:

|

LightWELDLaser welding power up to 1500 W, easily adjusted with intuitive controls to quickly dial in optimum weld settings for various materials and thicknesses.

|

LiGHTWELD XCExpands the welding capabilities of LightWELD with cleaning modes to quickly and easily remove oils, rust and coatings before welding, and removes debris and discoloration after welding.

|

LightWELd XrExtends the range of materials and thicknesses, enabling fabricators to benefit from a wide range of solutions. Pre-weld and post-weld cleaning functionality optimizes weld quality and productivity.

|

|

|

The handheld welding and cleaning gun is compact, ergonomic and comfortable- perfect for welding and cleaning applications. The specially-designed nozzle tips and built-in wobble functionality allow for consistent high-quality welds. Additionally, the nozzle tips can be switched out quickly to accommodate fusion welding, wire welding, and cleaning!

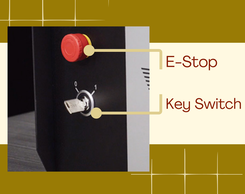

The system is incredibly user-friendly, with clearly labeled rear connections that make getting started quick and easy. Just plug in the power cord and gas connection, attach the workpiece clamp, and you're ready to go. Laser power, gas, and gun control are delivered through a single cable, while an ethernet computer connection provides access to advanced settings to fine-tune and save up to 74 stored preset and user-defined process parameters! With this functionality, new welders can be trained and welding in a matter of hours, boosting productivity and efficiency. |

|

|

LightWELD's built in safety features are great but you still must always wear PPE- like the laser safety glasses and helmet with shield provided with your machine. You’ll also need laser-resistant and heat resistant gloves, caps, a leather apron and other laser-resistant and heat-resistant clothing.

In addition to that, you'll want to keep those around you safe with a laser barrier. Learn about our recommended barrier options below! |

Barriers

|

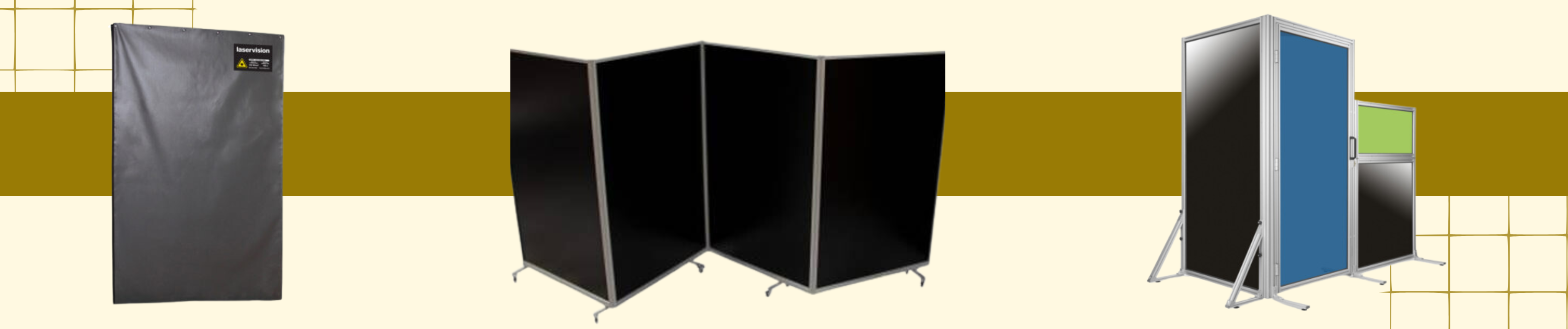

Safety is paramount for not only the LightWELD operator but also for those around. This is where laser barriers come in and there’s no one Earlbeck trusts more than LaserVision USA. They are a great resource for laser safety and recommendations. With Laser Curtains, Portable Laser Barriers, and Custom Laser Enclosures- they’ve got what you need or can do a custom application! You can find some of our favorite solutions below:

|

|

LaserVison USA's standard laser safety curtains are a great solution for immediate laser protection! They come in a variety of sizes that can be pieced together for larger coverage. Easily connect multiple curtains together with hook and loop fasteners to build a curtain that best suits your needs. If you are looking for a laser protection up to 575 W/cm2*, then a framed laser safety curtain is the best option for you. This portable barrier wall can be custom built this with strong, anodized steel hardware, locking casters, and laser rated-material. This offers excellent protection in a small environment!

Looking for even more protection? Give the foldable laser safety panels a try. Built with versatility in mind, these systems have unique 360° hinges so you can move and position your barrier according to your needs! Then once you’re done, it’s easy to fold up and store taking up less space than most barrier systems! Ranging from 2-6 panels, these are made with materials that have a laser safety rating of up to 10,000 W/cm2 for 100 seconds. None of those work for your application? What about their custom modular barrier system? This is a wall module system with frame that is customized to fit your laser environment! You’re easily able to incorporate laser safety windows and doors. The modular design allows for fast and easy construction. Plus, each segment can be equipped with wheels for a more portable solution. Don't believe they're the best? Well, you can check out Earlbeck’s custom built enclosure when you book your LightWELD demo today! |