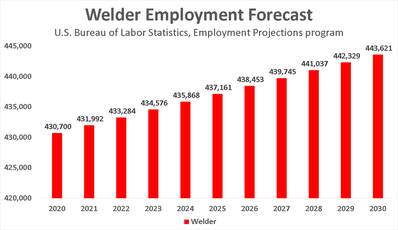

If we had to guess, it would be safe to say that we are all ready for 2021 to come to a complete close. Let’s just fuse the joints and keep burning. As we welcome and embrace the new year of 2022, let’s look at the projection for welders, career opportunities, and a few interesting events that have taken place since we began our journey into 2020. Read on more for inspiration for years to come! To the current and prospective welders, there will be a shortage of approximately 400,000 welders by 2024. The shortage is so large due to the boomer generation retiring from the industry. Welders can earn approximately $44,000 per year as a median projection and although welding as an industry typically requires certification, the welding career can be achieved with only a GED or High School Diploma regarding formal education. In 2019, there were 438,900 welding jobs available, and with the projected shortage of welders in the field, there will be more opportunities to come. There have been rumors about automated welding process replacing human welders, but that is not something to worry about. Fortunately for us humans, we can withstand certain conditions; and have the capability to accomplish welding projects that an automated process cannot. There will be opportunities for welders to learn how to operate the automated processes, as they require a welding operator to oversee and control the process. If anything, automated welding processes will provide more diverse opportunity within the industry. Here’s a list of some welding career opportunities based on the industry being served, first listing the top five: 1. Pipe Welding: These welders are in high demand, as they serve the gas, oil, and water utility companies. Welders will need to work on the pipelines carrying these valuable resources. 2. Aerospace Welder: This focuses on the equipment and technology used in airplanes. This type of welding is challenging, as there are many different welding processes and applications that are used and may also require off-ground welding. 3. Military Support: Welding in the military is not much different than civilian welding but requires the typical protocols of being in the military. Example: basic training is required, and it is within the various branches. One perk of pursuing this route is that there is no experience necessary, and the military will train. 4. Underwater Welding is challenging, as you can imagine. The underwater welder will have to accomplish the task at hand, while also attending to the risks associated with diving and being in the depths of water. 5. Certified Welding Supervisor monitors the welder, welding projects, ensures safety, and inspects the completed project for safety and compliance according to the appropriate code. 6. Autobody Technician / Custom Car Builders: When vehicles break down, damaged parts will need to be welded for repair, or to cut (remove) and install the appropriate part for a functional vehicle. 7. Shipbuilding and Repair: Inspects vessels and complete any necessary repair. (This may require travel along with the ship). 8. Rig Welders (Oil and Construction): This facet of welding is one of the biggest opportunities for welding in the oil and gas industry. Welders save companies significant amounts of dollars by repairing the rigs as they begin to show ware. This is physically demanding, as the welder will need to be on the job for a long period of time. 9. Jewelry Designer: For the individual that has a desire to create beautiful pieces that are intricate and delicate. They would also repair and resize the jewelry. 10. Boilermaker: assembles, installs, and repairs boilers or large-scale containers to hold gas or liquids Other types of industries for welding are: Industrial Maintenance Welders, Structural Steel Welders, Tool and Die Makers, Sheet Metal, Construction, and Motorsport.  To intrigue you even more, let's check out how interesting a career in welding can be and the opportunities that lie ahead. At NASA’s Michoud Assembly Facility in New Orleans, technicians from Lockheed Martin began welding the Orion Spacecraft, intended to land the first woman and next man onto the moon. The pressure vessel, being the primary structure, is comprised of seven machined aluminum alloy pieces that will provide an air-tight and habitable environment, while the astronauts travel through space and to withstand the harsh elements. The welding technology used is a Friction Stir Welding process. This process does not melt metal but causes friction that joins the two facing work pieces using a non-consumable tool. To read more of this story, you can check it out here.  Another recent accomplishment in the industry is the repair of the vintage aircraft called “The Chipmunk DHC-1”, which is named after the Canadian squirrel. This aircraft was a post war vintage aircraft developed in 1946 by De Havilland Aircraft of Canada; and as time moved forward, it was accessible to civilians. Repairing the aircraft was a challenge without the proper technology and sourcing parts was a financial endeavor. There have been many challenges to achieve this repair; and took over two years of research to accomplish since the aircraft is not favorable to the increasing temperatures caused by welding. The technology used is Cold Spray and known as Supersonic Particle Deposition (SPD) which uses either Nitrogen or Helium gas to propel metal particles to the aircraft parts, resulting in bonding of the metal. This process restores the part to its original blueprint dimensions, giving the Chipmunk DHC-1 another chance to soar the skies! Earlbeck Gases & Technologies is here to assist in the beginning of your welding journey and offers many different classes to achieve the goal of becoming a welder. It is crucial that we bridge the gap for welders and the industries served to ensure the sustainability of our world. Even though things seem uncertain, the welding world is the complete opposite. May we raise our torches and “toast” to the future that is as bright as the sparks we produce from our torches! AuthorJulia Brown, Customer Service Specialist/ Marketing Assistant |

- Products & Services

- Gases

-

Welder Training

-

Program Overview

>

- Pricing and Class Schedule

- How to Register

- Tour Our Facility

- Why Earlbeck Technical Center

- On Site Training

-

Frequently Asked Questions

>

- Are student loans, financial aid, or scholarships available?

- How long does it take to complete the program?

- What should I bring for my first day of class?

- Where can I find information about weather related closures or delays?

- Do you offer job placement?

- How Much Money does a Welder Make?

- What is the Job Outlook for Welders?

-

Program Overview

>

-

Weld Testing

- Welding 101 Blog

- Locations & Contacts

- More...

Baltimore, MD8204 Pulaski Hwy

Baltimore, MD 21237 Welding Supply & Gas Showroom Hours: Mon- Fri 7:30 AM - 5PM Phone: (410) 687-8400 Fax: (410) 687-1394 Welder Training & Testing Center Phone: (410) 687-8400 |

Beltsville, MD10792 Tucker St

Beltsville, MD 20705 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (301) 937-8884 Fax: (301) 937-1811 6170 Hughesville Station Place

Hughesville, MD 20637 Welder Training & Testing Center Phone: (410) 687-8400 |

York, PA95 Aberdeen Rd

York, PA 17406 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (717) 916-6611 Fax: (717) 764-1281 Welder Training & Testing Center Phone: (410) 687-8400 AACC Clauson Center for Innovation and Skilled Trades101 College Parkway

Arnold, MD 21012 Welder Training & Testing Center Phone: (410) 687-8400 |

Scranton, PA4961 Birney Ave

Scranton, PA 18507 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 5:00PM Phone: (570) 457-8954 3427 N Main Ave

Scranton, PA 18508 Welder Training & Testing Center Phone: (410) 687-8400 |

RSS Feed

RSS Feed