|

June is National Safety Month, an important time to reflect on and reinforce safety practices! Since welding involves inherent risks like exposure to intense UV radiation, infrared light, and flying debris, safety concerns are a top priority in our industry. Fire hazards and health risks from weld fumes add to the complexity of maintaining a safe work environment.

So let's talk safety- regular training and adherence to protocols are important for preventing accidents and promoting a culture of safety in the workplace. Today we're covering essential personal protective equipment (PPE), proper ventilation, proactive safety measures like the development of a comprehensive shop safety plan, proper cylinder handling, and more!

Conducting regular safety audits and walk-throughs with local emergency services can identify potential hazards and improve emergency response. Developing an effective emergency action plan based on this is incredibly important for any welding shop. According to OSHA, the plan must include procedures for reporting emergencies, evacuations, and accounting for all employees. It should also outline the duties of employees performing rescue or medical duties and designate contacts for more information. It's important to regularly update your emergency plan to reflect any changes made to your shop layout. It's also just as important to routinely conduct drills to be sure that all employees are ready for emergencies. Ongoing training and practice are essential to reinforce safety protocols and ensure readiness!

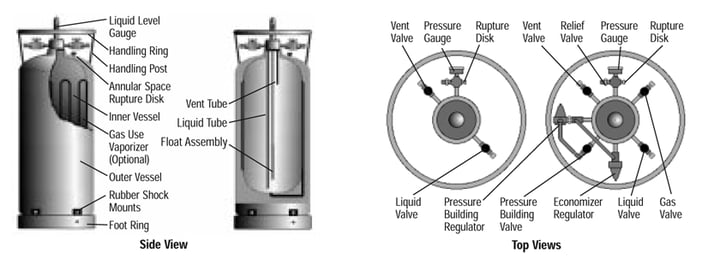

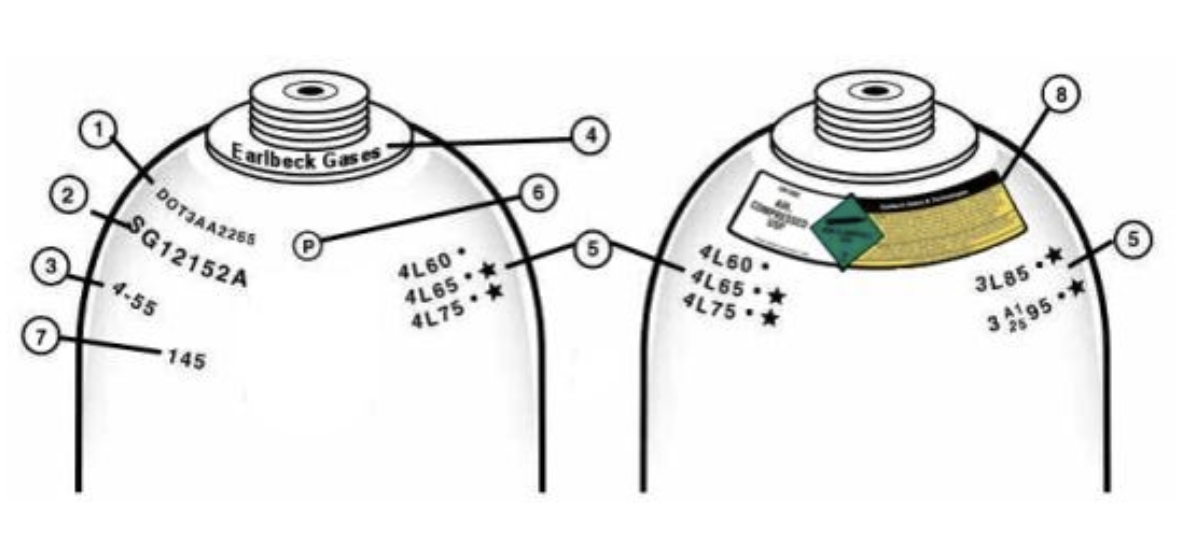

Valve Protection & Handling: Keep the valve protective cap in place when the cylinder is not in use, and never attempt to lift a cylinder by its valve protection cap! Use proper hand protection, such as gloves and avoid using tools to force or tighten the valve. After using a cylinder, make certain to close the valve tightly. Turn the valve until it stops, but avoid overtightening. No Grease or Oil: Never apply grease, oil, or any other lubricants to cylinder valves or fittings. These substances can react with certain gases and potentially trigger a fire or explosion. No Tampering: In the event of a faulty or damaged cylinder valve, never repair or modify it yourself. Notify your gas supplier! No Adapters: Each gas has a specific cylinder valve outlet connection. Mismatching these connections can result in hazardous reactions and contamination. |

|

0 Comments

|

RSS Feed

RSS Feed