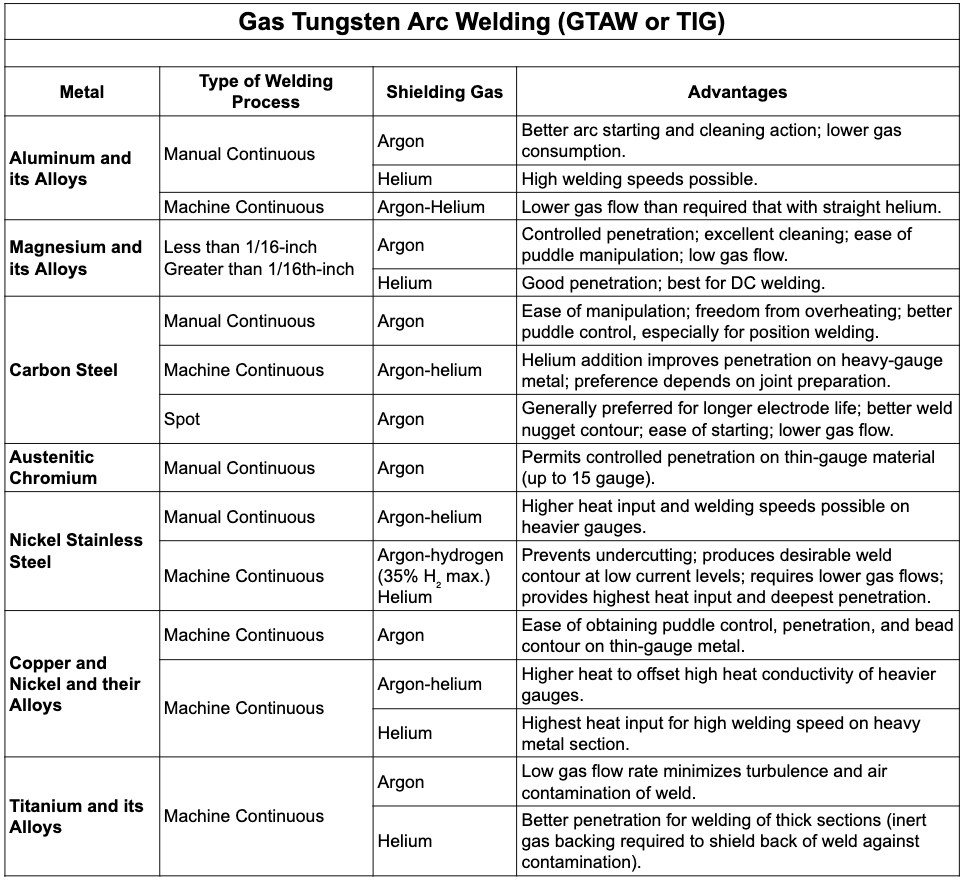

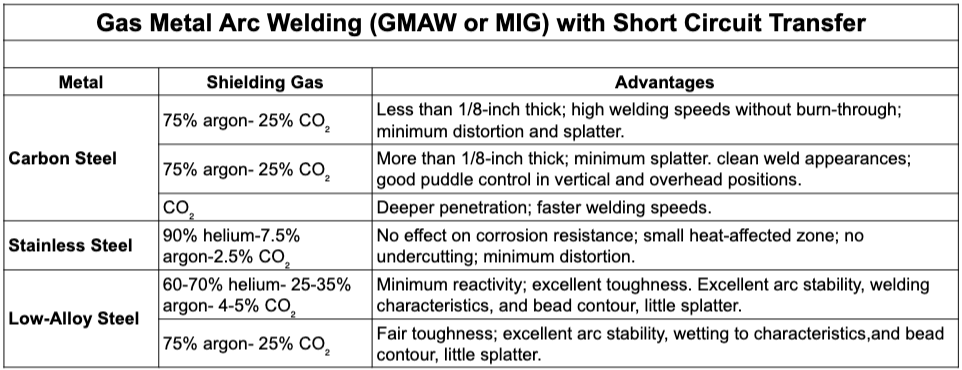

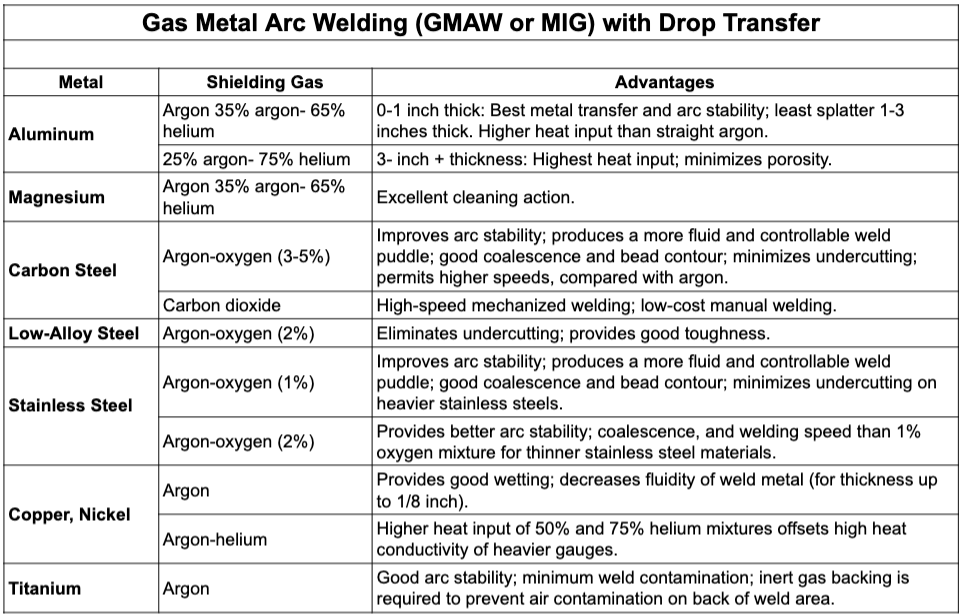

Shielding gases are used while TIG and MIG welding to protect your weld puddle from being exposed to oxygen, nitrogen, and hydrogen in the atmosphere. These elements can interact with the molten metal and cause defects in your weld. Shielding gases can also help with arc starting, cleaning, penetration, and arc stability. These gases play an important role on your finished product as well as your welding experience. With so many variations to pick from, welders commonly ask what is the best shielding gas for their application? Though the answer varies depending on the base metal and process, we've compiled a shielding gas selection guide to help with your selection. Our process engineering group is also available to do a free Gas Application Analysis to ensure you are getting the best results for your end product. ARGON As a shielding gas, argon provides the most stable arc combined with the most effective cleaning action. Argon offers welders excellent control of the welding arc and puddle. CARBON DIOXIDE Carbon dioxide is valuable in arc welding processes due to its high heat conductivity. Mixtures of carbon dioxide are often recommended to increase penetration of the weld. HELIUM Helium has a high voltage gradient and provides more heat than pure argon at equivalent arc lengths. Pure helium is excellent to use when the highest possible heat input is needed. Since helium is lighter and less dense than argon, two to three times as much is needed for equivalent shielding effectiveness. HYDROGEN Hydrogen provides high heat conductivity and reducing properties that make it a valuable shielding gas for stainless steel. It is also used to increase welding speed. Mixtures of hydrogen are often recommended to increase compatibility with certain materials. OXYGEN The heat conductivity characteristics of oxygen are useful for increasing welding speed and improving material soundness, penetration, and head shape. In order to help make gas selection easier, please see the below charts with recommended shielding gases for common applications. |

- Products & Services

- Gases

-

Welder Training

-

Program Overview

>

- Pricing and Class Schedule

- How to Register

- Tour Our Facility

- Why Earlbeck Technical Center

- On Site Training

-

Frequently Asked Questions

>

- Are student loans, financial aid, or scholarships available?

- How long does it take to complete the program?

- What should I bring for my first day of class?

- Where can I find information about weather related closures or delays?

- Do you offer job placement?

- How Much Money does a Welder Make?

- What is the Job Outlook for Welders?

-

Program Overview

>

-

Weld Testing

- Welding 101 Blog

- Locations & Contacts

- More...

Baltimore, MD8204 Pulaski Hwy

Baltimore, MD 21237 Welding Supply & Gas Showroom Hours: Mon- Fri 7:30 AM - 5PM Phone: (410) 687-8400 Fax: (410) 687-1394 Welder Training & Testing Center Phone: (410) 687-8400 |

Beltsville, MD10792 Tucker St

Beltsville, MD 20705 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (301) 937-8884 Fax: (301) 937-1811 6170 Hughesville Station Place

Hughesville, MD 20637 Welder Training & Testing Center Phone: (410) 687-8400 |

York, PA95 Aberdeen Rd

York, PA 17406 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (717) 916-6611 Fax: (717) 764-1281 Welder Training & Testing Center Phone: (410) 687-8400 AACC Clauson Center for Innovation and Skilled Trades101 College Parkway

Arnold, MD 21012 Welder Training & Testing Center Phone: (410) 687-8400 |

Scranton, PA4961 Birney Ave

Scranton, PA 18507 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 5:00PM Phone: (570) 457-8954 3427 N Main Ave

Scranton, PA 18508 Welder Training & Testing Center Phone: (410) 687-8400 |

RSS Feed

RSS Feed