| Throughout history, humans have used containers to store, transport, and dispense items. Regardless of the era, it is generally the case that what’s inside a container is more important than the container itself. However, when it comes to cryogens, the considerations and specifications behind their storage cylinders give these containers special notoriety. In order to properly choose and use liquid cylinders, it is important to understand their make up as well as any considerations for their care and storage. What are Liquid Cylinders and What are They Used For? A liquid cylinder, sometimes called a “liquid flask” and most commonly known as a “dewar” is a double-walled, vacuum-installed container used for storing cryogens. A dewar acts like a thermos in that it keeps atmospheric gases well below ambient temperatures (sometimes as low as -400 degrees F) so that they are stored in their liquid states. Commonly stored cryogens include liquid nitrogen, liquid argon, liquid oxygen, and liquid helium. Depending on the design and features, dewars can dispense the elements as gas, liquid, or both. Although dewars used for temporary storage may be made out of foam insulation, most are made from metals such as aluminum or steel. Cryogens themselves are used in many applications, such storing food, cooling superconductors, and freezing lab samples. They are also used in MRI machine functioning, producing cryogenic fields for rockets, and performing cryosurgeries. The benefit of dewars is that just one of them can function like many gas cylinders. This superpower is achieved by the dewar’s ability to house pressure far larger than its natural productive capacity. Because their functionalities can be equivalent to 20 high pressure cylinders, it is easy to surmise that even a single dewar can save precious storage space while significantly cutting back on costs. |

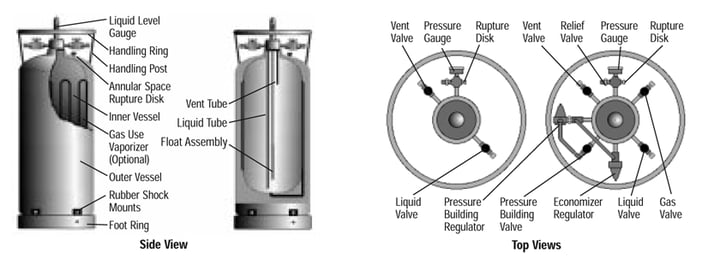

| Anatomy of a Liquid Cylinder The construction of a liquid cylinder can be simple or complex depending on its purpose. Although common working pressures include 22, 180, and 230psi, dewars can be custom designed to accommodate other pressures. Although a cylinder is the most-common shape, dewars can also be crafted into other dimensions. Additionally, they can be outfitted with handles, legs, various drain locations, outlets, and caster mountings – whatever is needed to help the dewar fulfill its intended use. Regardless of the shape they ultimately take, most dewars share the same, internal anatomy. The most visible part of a dewar is the outer vessel, which is the metal surface that makes up the dewar’s shape and protects the inner vessel where the liquid tube and vent tube are often housed. The combination of the outer and inner vessels allows the dewar to function. Opening a pressure building valve at the top of the tank draws liquid through the liquid tube and through a pressure building coil. As the liquid travels through the tube, it transforms into its gaseous state by the warmer temperature outside of the inner vessel. This process, sometimes known as the Vaporizer Circuit, increases pressure within the canister that can be harnessed to dispense the gas. Many cylinders have an Economizer Circuit which prevents gas losses from venting by storing extra pressure that may build up when the cylinder remains unused for a time. When the internal tank pressure reaches a specific psi, a regulator allows gas to flow through an internal vaporizer in order to reduce inner-tank pressure. When pressure normalizes, the regulator closes and the cylinder functions normally. At the top of most dewars is a system of gauges and valves responsible for monitoring and releasing the gas. As its name suggests, the pressure gauge indicates the pressure inside the inner vessel. Typically attached to the pressure gauge is a pressure control valve. The gas-use valve and liquid-use valve draw gas or liquid forms out of the dewar for use. The pressure building regulator controls the rate of pressure build while a liquid contents gauge measures how much liquid is left in the tank. Care and Considerations It is beyond question that caring for cryogens and their storage containers requires careful consideration. First, it is important to have a working knowledge of the different types of gases and what each might do under certain conditions. For example, since frost often form outside of dewars due to prolonged usage or a pressure valve being left open, it is advisable to keep a drip tray or pan under the dewar to avoid water damage. Second, it is important to know and follow each cylinder’s specifications and instructions exactly. Cryogens should NEVER be stored in containers that are not specifically designed for them because each cylinder has different venting and temperature regulation abilities. This logic also applies to any hoses, valves, regulators, gas detectors, or other containers that may be involved in manipulating the cryogens. While there may be room for error in storing/transporting some substances, cryogens are not among them. Third, it is important to know how to protect the person who will interact with the cryogens and liquid cylinders. Safety equipment, including glasses, gloves, face shields, closed toed shoes, lab coats or other protective clothing, etc. should be used at all times. Whenever possible, the person working with the dewars should receive any training or instruction that is available on use and safety/emergency practices. Please consult with your gas supplier for the latest training on safe handling procedures. Final Thoughts When proper care is given to operating liquid cylinders, their economic, industrial, and scientific benefits can be enjoyed. While it may require extra effort, keeping educated about the anatomy of the cylinders, the nature of the atmospheric gases that they house, and current safety practices will ensure that dewars and their contents achieve their purposes. |

RSS Feed

RSS Feed