| The metal fabrication industry faces a multitude of challenges that seemingly increase in complexity with each passing day- reshoring efforts, supply chain obstacles, rising wages, an aging population of skilled workers, and a historically low unemployment rate among younger generations are creating a domino effect. These challenges are no longer merely affecting lead times and margins, they now pose a risk to the fundamental ability of fabricators to maintain their business and their relationships with customers. Many organizations are hesitant to adopt even simple automation solutions, despite the proven benefits of widely-used ones. This resistance to change may be due to fear of the unknown. However, when handled correctly, change can be a catalyst for growth and learning. In fact, it is crucial for businesses to adapt in order to remain competitive and relevant. Failure to change can leave your business behind the times and with automation rapidly becoming necessary to keep up with customer demands, will your business embrace the change? |

|

1. Set Clear Company Expectations

As automation becomes more prevalent, it is important to consider the impact it will have on company culture. Its essential to set clear expectations. Determine what your business wants to achieve with automation, and what outcomes to expect. This is not a one-size-fits-all solution and the right approach will depend on the goals, structure, culture and values of each organization. Automation is often misperceived as a potential threat to jobs. However, this is not the case. Workers who become proficient in robotics and automation can expand their skill set, improve career prospects, and become more valuable to the company. For example, a welding cobot operator can program the desired welding path using all of the experience they've gained over the years, which enables them to reduce fatigue from repetitive motion, create a consistent product with reliable quality, and get more done with less sweat. Identifying and encouraging automation experts will help your company’s growth and communicating your plan clearly with what the intent will be for each stakeholder will help ensure a smooth roll out. Communicate thoroughly and often! Automation should be included in your business plans, but it may not be a solution to every problem you face. It's highly efficient at resolving specific issues and can create unexpected possibilities for innovation. Not only does automation save money, but it also increases revenue. To achieve success, you'll need dedicated program champions on your teams who have the ability to set clear goals, communicate effectively, and conduct thorough progress reviews. 2. Choose the Right Process to Automate

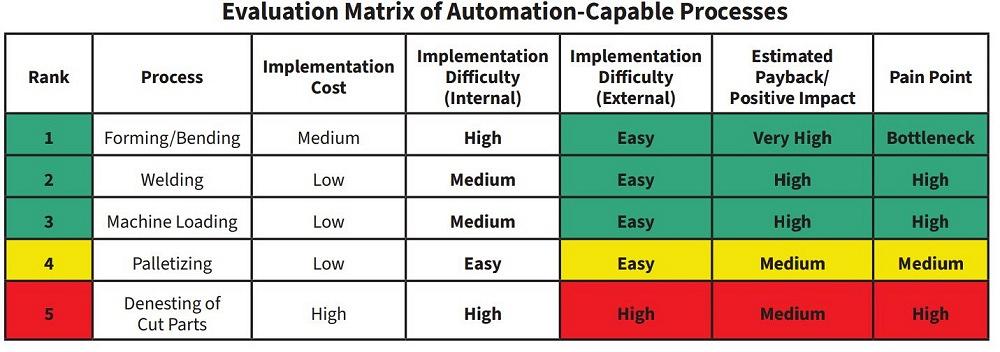

Effective automation solves the right problems with ease. However, it is important to select the right processes to automate, in the correct order, and match them with the best automation technology for the job. Rank targeted processes based on risk and overall impact on the business to find where to start.

Strike a balance between cost and complexity- certain industrial robots are a great fit for massive productions of uniform parts, despite their high initial price point. For simple operations with minimal variation, lower-cost devices are more appropriate. However, when you're dealing with small to large quantities that have significant part variability, flexible systems like adaptive collaborative robots (cobots) offer a cost-effective and optimal solutions. Previously, the decision to automate hinged on a basic ROI calculation – a straightforward analysis of production volume and cost savings. However, the current landscape is far more complicated. While ROI calculations are still useful, a bottleneck caused by idle machinery can have a greater impact on a company's profits. For instance, if a major product can’t be shipped due to the absence of inexpensive fabricated parts, then the actual payback is determined by the revenue loss resulting from the bottleneck. This financial repercussion can be many times larger than what a simple ROI calculation would suggest. One effective approach to improving efficiency is to prioritize impactful processes according to your business needs. When determining which processes to prioritize, it is important to keep in mind that every factory has different variables to consider. Among the most commonly assessed factors are the cost as a percentage of revenue, impact on customer lead times, difficulty of acquiring skilled operators for the machinery, workflow bottlenecks, unacceptable quality levels, safety issues, workstation idle time, complexity of integration, and overall process pain points. The Fabricator "5 Steps to Automation Success in Metal Manufacturing"

If a work element is widely disliked by many involved, it is likely a good candidate for improvement. If you chart these variables in a simple graphic that measures overall business impact and implementation difficulty, decision-making can be easily streamlined. This helps narrow the selection to a small, more manageable, number of potential targets. Decision-making is both an art and a science, so it's not always beneficial to overthink. Choose the process that seems to offer the best balance between implementation complexity and business benefit at this stage, and begin with that. It's important to honestly evaluate your company's existing engineering/automation capabilities. If you have some internal resources and want to self-integrate, pay special attention to the integration difficulty. Remember not to take on too much work at once, but keep in mind the level of automation you are willing to start with. This might mean starting with something as simple as a single-axis pick-and-place device that moves workpieces from point A to point B. Or, it could mean highly customized industrial robots that are appropriate for high-volume output of stable workpieces. Somewhere in the middle, you'll find devices such as cobots that are both flexible and relatively simple to adapt and program. No matter what kind of automation you're dealing with, safety must always be a top priority. Automated systems should be deployed securely, and safety costs and employee training should be included in the budgeting stage of project planning. Keep in mind that the complexity of the process, as well as the time and capital required, and the volume of the chosen parts being built, will all factor into the final decision. 3. Re-Work the Process for Automation

When it comes to automation, simply replicating manual operations is not common. Instead, you must re-engineer processes to fit within the context of overall manufacturing flow.

A good first step is to generate a simple map of manual processes. This first map just needs to accurately describe the elements in the process. After you’ve completed that, analyze which factors may affect it. Consider the following:

After addressing these fundamental issues and establishing a strong foundation, you’ll want to come up with a clear and concise list of critical goals and deliverables. Aim to set up a review process to make sure the initial goals are still relevant. Remember, automation doesn't replace existing tasks but requires a complete rethinking of the manufacturing process. You won’t help yourself, your employees, or your company if you invest in automating a process that already produced poor results. Embrace the opportunity to identify and resolve underlying problems that may have gone unnoticed. Another critical factor is often the most difficult to address: an honest and realistic evaluation of available internal resources and skills. Foremost is the designation and empowerment of one or more automation champions. They don’t necessarily need to be highly experienced and skilled in automation, but they should thoroughly understand your existing processes and your automation project goals. In addition, they must be allowed to focus on the project rather than be forced to treat it as a once-a-week diversion. These core team members can relinquish some project control to others, but it's essential to maintain a balance between that control, their technical expertise, and the integrator’s scope of experience. It's important to consider the potential for a shorter ROI as well. Before partnering with an integrator, review their relationship with existing customers and examples of their previous outcomes. Even when working with other integrators, project implementation, feedback, and schedule focus require clear communication channels with any integration team. A designated individual is needed to make this process run smoothly. So you have your deliverables outlined, you’ve set your staff up for success with tools and time, and you’ve clearly defined your integrator's roles. What next? Time to review the project deliverables with fresh eyes and focus! You need clearly defined and documented plans for the process and your team and a periodic review set up that will keep everything in check. Be sure in your final check that the deliverables align with these expectations, and that they are realistic and achievable within the planned time frame (and crucially budget). It’s important to stay within these parameters to avoid failure due to unrealistic expectations. Step one won’t solve all the company’s problems in one fell swoop. 4. Keep Up The Good Work

Keep up with documentation on the process’s performance and overall impact. A great indicator of success, beyond enhanced revenues and ROI, is employee knowledge growth. Learn from the outcomes of this first process and apply it in the future! Take note of potential candidates for future automation, how to pick the right equipment and individuals to get the job done, and how to predict timelines and financial benefits. 5. Record Data= Gain Insights

It's critical to document both hits and misses throughout the process. These insights are incredibly valuable, as they lay the groundwork for future automation projects. Furthermore, you can replicate successful automation strategies for other processes in your business. When documenting your progress, be truthful and clear, but don't forget to celebrate your successes! Use this information to make informed decisions when selecting your next project. Armed with this knowledge, you can take future productive steps in your automation journey. |

| While technology can solve many problems, it's not a cure-all solution. As some early adopters have cautioned, it takes a thoughtful and methodical approach to automation to achieve success. A clear plan, the right team, thorough prep, and well-defined expectations are critical to any initiative's success. Automation presents an opportunity to gain a deeper understanding of your operations, foster innovation, and establish valuable processes and institutional knowledge. Identify and nurture capable team members and you’ll see a marked increase in your profits. Above all, managed automation can improve customer relationships ensure your company’s relevance in the ever-changing business landscape of today! Reach out to Earlbeck today to get help forming your automation plan! Whether you’re starting from scratch or just trying to expand on what’s working for you already, we’ve got suggestions for you! |

RSS Feed

RSS Feed