| Machinery, automobiles, aircraft, and office/residential buildings all require welding to help society function with safety and ease. While many activities have a margin for error, welding is not one of them. Just imagine the devastating consequences of poor welding on a nuclear power plant! Thankfully, the welding industry has various means to test the strength of welds before they are used in production. There are destructive tests which involve physically destroying a completed weld to assess its infrastructure; and non-destructive tests, which check for defects and discontinuities without causing damage to the part. |

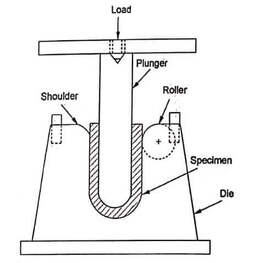

| Understanding the different testing methods and what each evaluates gives your quality control team options for ensuring your weld is fit for service. Whether used for failure analysis, welder performance qualification, or sample or research inspections, destructive weld tests detect crack initiation and other defects before it's too late. Fillet Weld Break Test As its name suggests, fillet weld break tests involve breaking a fillet weld that is fused on only one side. The test is most often conducted on a 6 to 12-inch section. The break (destruction) occurs by using a press to apply weight to the unwelded side until the weld fails. The sample is then examined for flaws. This test is typically used to check for the following defects: · Slag inclusions · Internal porosity · Lack of fusion · Linear fusion defects Because it reveals discontinuities within the length of the weld, the fillet weld break test is the way to go to determine the EXTENT of a weld’s defects. Guided Bend Test  Once again, this test keeps to its name. A welding specimen is bent to a predetermined radius along a wraparound bend test jig or another test machine. Welders can conduct both face and root bend tests using this method, using side bends to assess thicker sections. Guided bend tests are particularly adept at assessing: · Ductility · The soundness of welded joints · Linear fusion defects This is also the most commonly used assessment in welder performance qualification tests. Macro Etch Testing Macro etch testing is a highly successful test that removes small samples from the welded joint. The samples are polished at their cross sections before a mild acid mixture (which varies depending upon the base material) is used to etch the joint. The etching, with particular focus on the fusion line, provides insights into the internal structure of the weld. Characteristics that this test appraises are: · Fusion (or lack thereof) · Penetration depth · Cracking and inclusions · Internal porosity To understand the OVERALL weld-length quality of production welds at the cross-section, use the macro etch testing method. Traverse Tension Test The traverse tension test is used to evaluate a welded joint’s tensile properties. The test is conducted by exerting pulling forces on specimens until the joint fails. Welders then divide the maximum load required during testing by the cross-sectional area to read the units of tension per cross-sectional area. Because tensile properties of welds (which involve ductility and soundness) are vitally important to manufacturing designs, this test is one of the most crucial to the industry.  Teach to the Test? In many industries, the concept of “teaching to the test” is generally frowned upon. The thought is that teaching skills exclusively to achieve certain test scores restricts a student’s capacity for creativity and real-world scenarios. However, when it comes to welding, meeting the criteria of the welding code for your application can mean the difference between life and death for customers. From its pervasive role in everything from transportation and housing to tools and technology, welding is an integral part of modern society. It is the welding industry’s responsibility to ensure that welded products maintain the integrity to perform their intended tasks. If you need destructive or non-destructive weld testing, give the Earlbeck Technical Center team a call at (410) 687-8400 and we will help you select and implement the correct test for your product's service. |

RSS Feed

RSS Feed