|

In recent years, technological advancements have revolutionized the welding industry, and one such innovation that stands out is heat induction machines. This technology boasts nearly two decades of successful applications across all kinds of industries such as industrial and construction welding, refineries, chemical plants, pipeline construction, shipbuilding, and more. The process plays a critical role in welding applications that demand preheating to bridge the temperature gap between the welding arc and the base material. By doing so, it not only decelerates the cooling rate of the weld but also reduces hydrogen presence, significantly lowering the likelihood of cracking and weld failure.

Induction heating stands out for its ability to drastically cut down on time and ensure uniform temperature control when preheating or post-weld heat treatments are required. It also improves safety and weld quality, marking it as an invaluable tool for time and cost savings! Induction heating helps the process by preheating the base material, or at least the area around the weld joint, to a precise temperature before starting the weld. This method employs electromagnetic fields to heat the workpiece. Basically the welder can place the tools on or around the conductive object and the magnetic field will produce eddy currents within the metal, which agitate the molecules and creates heat! This makes the object itself the heat source, rather than the heating equipment.

This precise heating mechanism allows for uniform temperature distribution, minimizing distortion and preserving the integrity of the workpiece. And on top of that, there is much less safety risk for the welder compared to the slower, more cumbersome resistance or open flame methods- ensuring an overall more cost-effective heating solution.

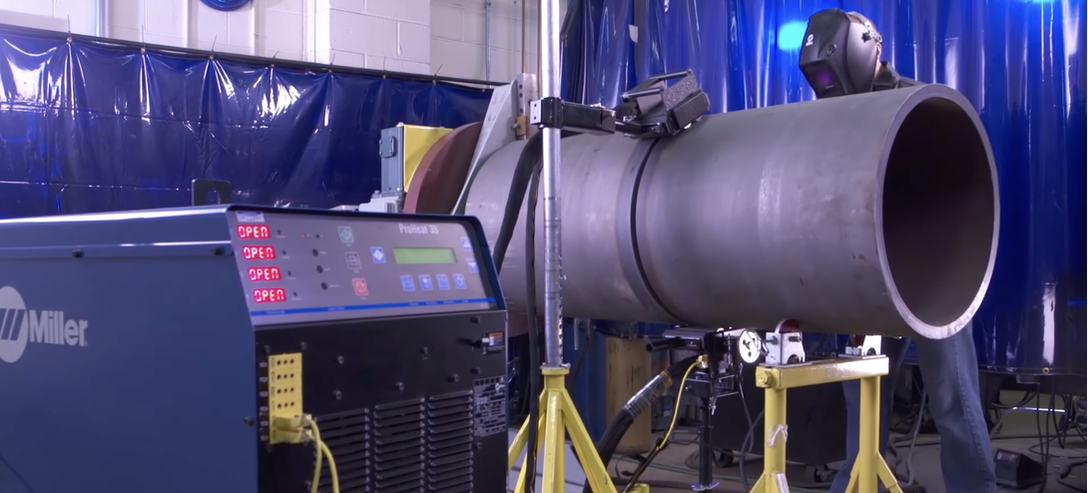

The air-cooled option allows operators to effortlessly use flexible blankets or cables, suitable for a wide array of preheating needs up to 400°F, without the necessity for additional cooling equipment, streamlining the process and cutting down costs. While the liquid-cooled component caters to more demanding applications that need high-temperature preheating and stress relief up to 1,450°F. The liquid-cooled option distinguishes itself with a water cooled flexible hose for the induction coil, complemented by a built-in temperature controller and recorder for precise heat management. Lastly, the rolling induction component is designed to accommodate the dynamic environment of pipe welding in fabrication shops. Because rolling the pipe eliminates out of position welding, the welder is able to boost productivity with higher wire feed speeds and deposition rates. This component can heat the part while it moves and the welder works, delivering fast and consistent heat up to 600°F!

Not only does this system stand out for it's ease of use, speed, safety, and cost-efficiency but it's also engineered to work seamlessly with existing welding power sources- simplifying operations and reducing expenses! Companies can internalize preheating processes using on-site welding power sources, often heating a joint to the required temperature in 20 minutes or less!

These heaters are compatible with a variety welding power sources, including all XMT® 350 FieldPro™ models, Miller engine-driven welders/generators with ArcReach technology, and any Miller power source capable of operating a Smart Feeder. Induction heating has emerged as a versatile and efficient solution across a broad spectrum of industries and applications, showcasing exceptional flexibility! We all know it excels in scenarios like preheating roll pipe in fabrication shops but it can also play a pivotal role in enhancing operational efficiency and safety in many other industries and applications. Beyond the typical application in pipe welding, induction heating can be used for flat plate and other unique geometries.

Induction heating finds its application in preheating and maintaining weld temperatures, hydrogen bake-outs, post-weld heat treatments, shrink-fit processes, and more. Industries benefiting from this technology include oil and gas, structural, power plants, petrochemicals/refineries, process/power piping, pressure vessels, shipyards, and mining. Exploring beyond traditional applications reveals induction heating's potential in fields like heavy equipment construction and maintenance and repair of mining equipment. For instance, overcoming challenges such as the heat sink effect of flowing oil in oil pipeline maintenance or achieving more efficient and safer preheating methods in natural gas pipeline construction. Similarly, in power plant construction, switching to induction heating from less reliable methods has resulted in faster heating times and reduced construction delays. These examples hint at the broader possibilities for applying induction heating across various settings, emphasizing its role in not only meeting but exceeding the operational and safety standards of today's industries. Whether for complicated part geometries or demanding environmental conditions, induction heating offers a promising avenue for efficiency and innovation. It's not an overstatement to say that this technology saves money in both time and resources! When you consider the cost of outsourcing weld preheating to a specialized company, or installing expensive primary electrical power for resistance heating, or even the propane costs for flame heating- then factor in the additional expenses for fire-watch personnel and the sheer amount of time traditional preheating methods can take - you'll easily see the contrast! |

- Products & Services

- Gases

-

Welder Training

-

Program Overview

>

- Pricing and Class Schedule

- How to Register

- Tour Our Facility

- Why Earlbeck Technical Center

- On Site Training

-

Frequently Asked Questions

>

- Are student loans, financial aid, or scholarships available?

- How long does it take to complete the program?

- What should I bring for my first day of class?

- Where can I find information about weather related closures or delays?

- Do you offer job placement?

- How Much Money does a Welder Make?

- What is the Job Outlook for Welders?

-

Program Overview

>

-

Weld Testing

- Welding 101 Blog

- Locations & Contacts

- More...

Baltimore, MD8204 Pulaski Hwy

Baltimore, MD 21237 Welding Supply & Gas Showroom Hours: Mon- Fri 7:30 AM - 5PM Phone: (410) 687-8400 Fax: (410) 687-1394 Welder Training & Testing Center Phone: (410) 687-8400 |

Beltsville, MD10792 Tucker St

Beltsville, MD 20705 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (301) 937-8884 Fax: (301) 937-1811 6170 Hughesville Station Place

Hughesville, MD 20637 Welder Training & Testing Center Phone: (410) 687-8400 |

York, PA95 Aberdeen Rd

York, PA 17406 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (717) 916-6611 Fax: (717) 764-1281 Welder Training & Testing Center Phone: (410) 687-8400 AACC Clauson Center for Innovation and Skilled Trades101 College Parkway

Arnold, MD 21012 Welder Training & Testing Center Phone: (410) 687-8400 |

Scranton, PA4961 Birney Ave

Scranton, PA 18507 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 5:00PM Phone: (570) 457-8954 3427 N Main Ave

Scranton, PA 18508 Welder Training & Testing Center Phone: (410) 687-8400 |

RSS Feed

RSS Feed