In order to identify which stick electrode you should use, their is a system of classification that takes the form of numbers and letters printed on the sides of stick electrodes. Always check the welding specification and procedures for the electrode type, especially for critical applications.

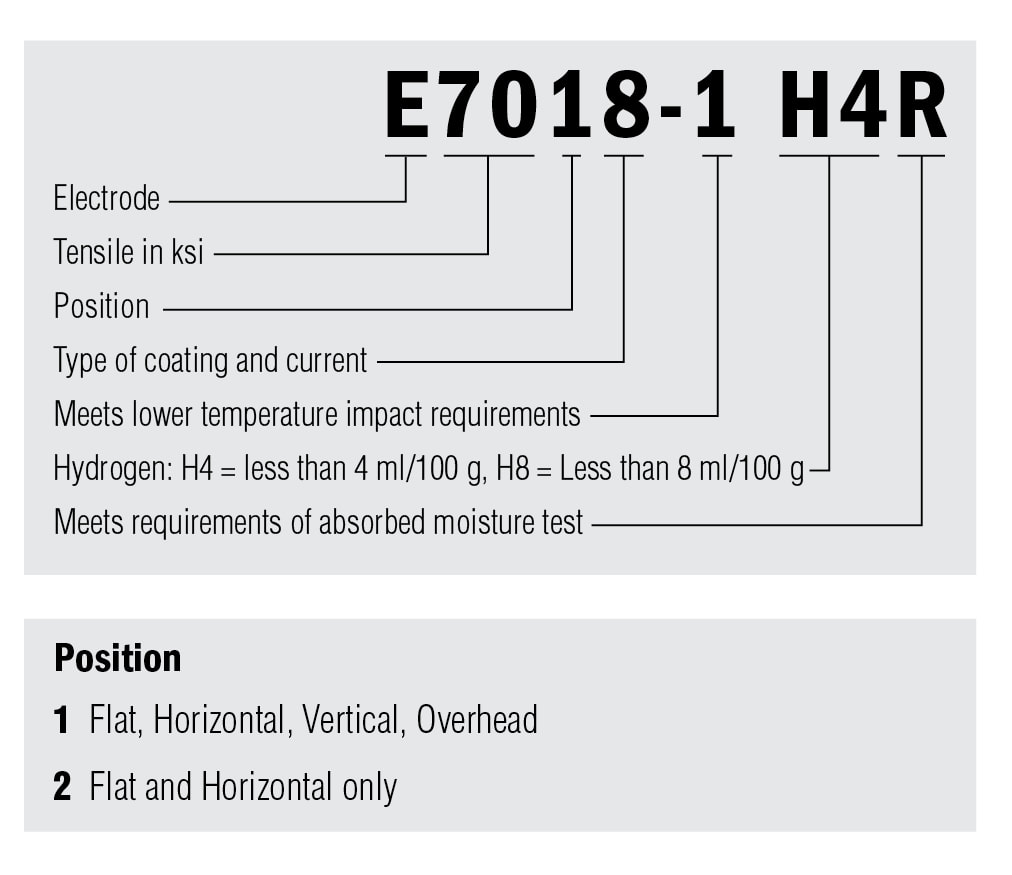

Here’s how the classification of the AWS system works:

- "E" indicates electrode.

- The first two digits represent the weld's minimum tensile strength (in PSI). An example, the number 60 in an E6010 electrode indicates that the electrode will produce a weld bead with a minimum tensile strength of 60,000 PSI.

- The third digit indicates the welding position(s) for which the electrode should be used.

- 1 means the electrode can be used in all positions

- 2 means it can be used on flat and horizontal fillet welds only

- The important fourth digit represents the coating type plus the type of current (AC, DC or both) that can be used with the electrode.

| First, select the stick electrode that matches the strength properties and composition of the base metal you will be working with. Next, match the electrode type to the welding position (1 or 2) and consider the available power source. Remember, certain electrodes can only be used with DC or AC, while other electrodes can be used with both. Inspect the joint and fit, then select an electrode that will provide the best penetration characteristics (digging, medium, or light). To avoid weld cracking on thick, heavy material and/or complicated joint designs, select an electrode with maximum ductility. Do not neglect the service condition the component will encounter and the specifications it must meet; low temperature, high temperature, or shock-loading environment for example. A low hydrogen E7018 electrode works well. Also, consider production efficiency. When working in the flat position, electrodes with a high iron powder content, such as E7014 or E7024, offer higher deposition rates. For critical applications, always check the welding specification and procedures for the electrode type. |

Properties of Electrodes:

The most common stick electrodes in the American Welding Society (AWS) A5.1 Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding include E6010, E6011, E6012, E6013, E7014, E7024, and E7018.

- E6010 Electrodes

- DC power sources only.

- Deep penetration with the ability to get through rust, oil, paint, and dirt.

- Extremely tight arc, ideal for more experienced welders.

- General-purpose fabrication and maintenance welding.

- X-ray quality welds out-of-position also good for vertical and overhead.

- Flat beads with distinctive ripples; light slag.

- E6011 Electrodes

- AC power sources/can be used with DC if necessary.

- Able to use for all-position welding. General-purpose fabrication and maintenance welding.

- Produces a deep, penetrating arc with maximum admixture that cuts through metals.

- X-ray quality welds out-of-position.

- Flat beads with distinctive ripples with light slag.

- E6022, E7010, E8010, & E9010

- DC power source

- General-purpose fabrication and maintenance welding.

- X-ray quality welds out-of-position; good for vertical and overhead.

- Deep penetration with maximum admixture.

- Flat beads with distinctive ripples and light slag.

- E6012 Electrodes

- AC & DC power sources.

- Solid choice to gap bridging between two joints.

- Boasts high-speed, high-current fillet welds when in the horizontal position.

- Tends to produce a shallower penetration profile and dense slag.

- Usually requires additional cleaning.

- Medium deposit rates and medium penetration.

- Smooth ripple-free to even with distinct ripples.

- E6013 Electrodes

- AC & DC power sources.

- Soft arc with minimal spatter.

- Medium deposit rates and medium penetration.

- Moderate penetration and easily-removable slag.

- Used to weld clean, new sheet metal ONLY.

- Smooth ripple-free to even with distinct ripples.

- E7014 Electrodes

- AC & DC power sources.

- Produces almost equal joint penetration as E6012 electrodes, but can be used at higher amperages.

- Designed for use on low-alloy steels and carbon.

- The deposition rate increases due to a higher amount of iron powder.

- Medium deposit rates and medium penetration.

- Smooth ripple-free to even with distinct ripples.

- E7018 Electrodes

- AC & DC power sources.

- Deemed one of the easiest to use, they contain a thick flux with high powder content.

- Produces a smooth, quiet arc with minimal spatter and medium arc penetration.

- Used by many to weld thick metals like structural steel; also when welding carbon and low alloy steels that require 70,000 PSI tensile strength deposits.

- These electrodes produce dense, x-ray quality welds with high-impact properties (cold weather) and can be used on high-strength steel base metals, carbon steel, low-alloy, or high-carbon.

- Can be used for these applications: low-temperature, high-temperature, or shock-loading environments.

- E7028 Electrodes

- AC & DC power sources.

- Fast-fill, low hydrogen group

- Welding carbon and low alloy steels that require 70,000 PSI tensile strength deposits.

- Produce dense, x-ray quality welds with notch toughness properties.

- E7024 Electrodes

- Direct and Alternating currents can be used (DC & AC)

- Deposition rates increase due to a high amount of iron powder.

- Used by many for high-speed horizontal or flat fillet welds; also slightly downhill position. (15” maximum)

- These electrodes perform well on steel plate at least ¼ inch thick or metals that measure over ½ inch thick.

- Smooth ripple-free beads are flat or slightly convex with minimal splatter and easy slag removal.

- E6027 Electrodes

- AC & DC

- Highest position rates of all electrodes.

- Flat, horizontal/slightly downhill position only. (15” maximum)

- Smooth ripple-free beads are flat or slightly convex with minimal splatter with easy slag removal.

RSS Feed

RSS Feed