THE GULLCO KAT® WELDING AND CUTTING CARRIAGETHE MOST DURABLE, DYNAMIC, AND VERSATILE CARRIAGE IN THE INDUSTRYEarlbeck Gases provides Welding & Cutting Automation products to help manufacturers reduce rework and improve productivity. We have partnered with Gullco to provide welding and cutting carriages due to their light weight design, simple set up, and quality manufacturing. The Gullco KAT® is used throughout the world to automate a wide variety of welding and cutting operations. The KAT® is small and light yet robust with many features which include:

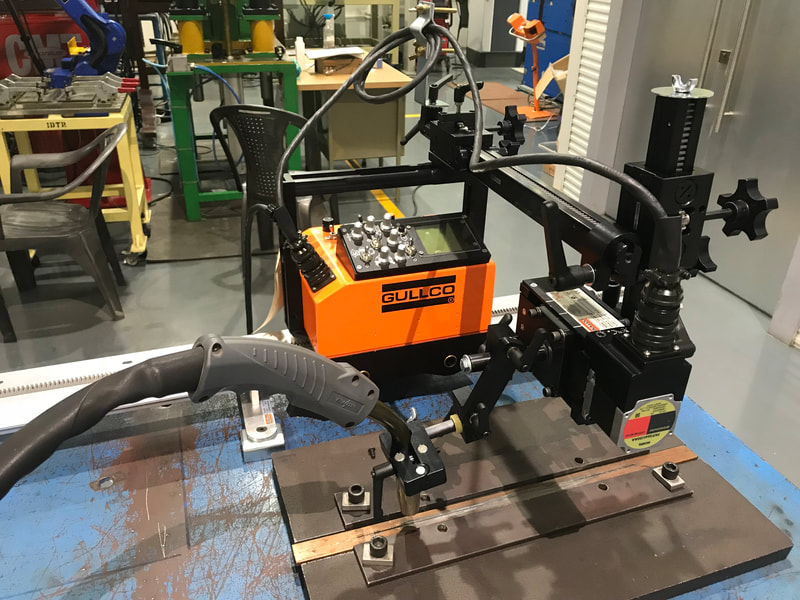

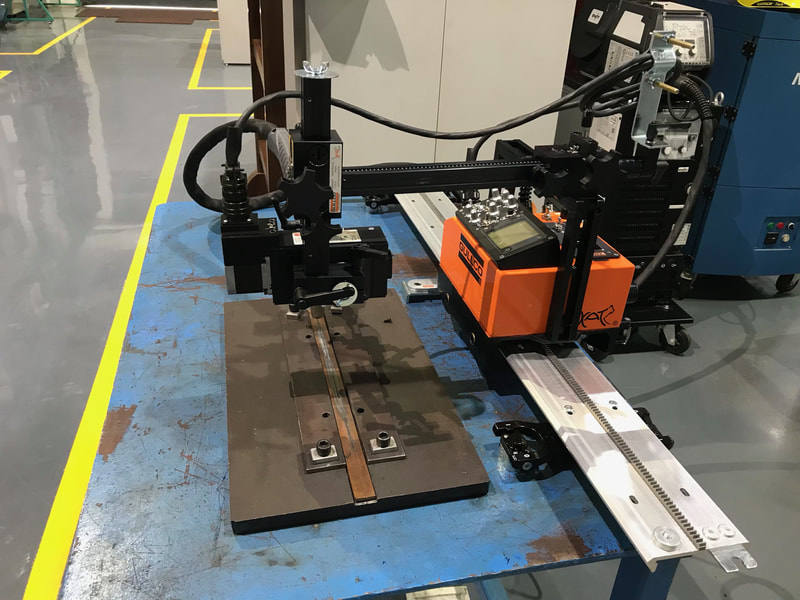

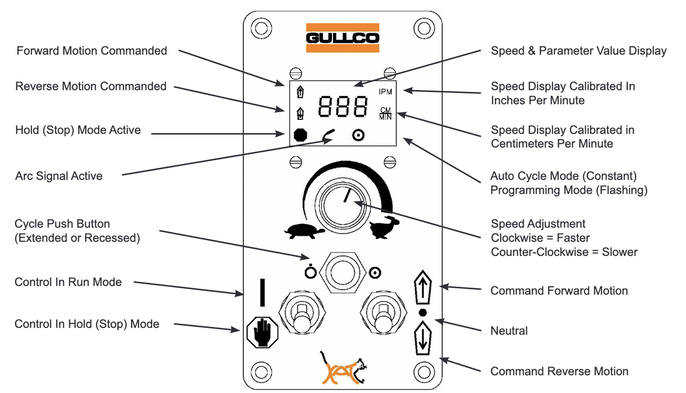

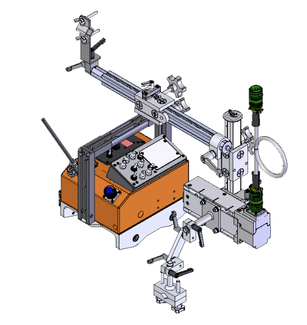

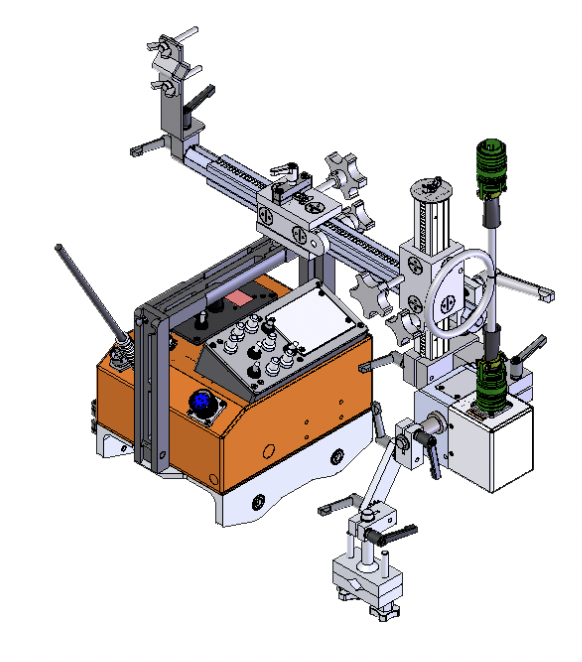

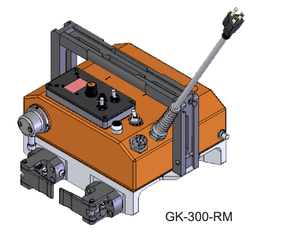

Welding guns or cutting torches mounted on the KAT® carriage move along track at precisely controlled speeds along the desired path in forward or reverse direction. Gullco's Rigid KAT® carriage enables welding guns or cutting torches to operate with precise motion from start to finish regardless of the number of passes or the work pieces involved. By adopting this automation great improvements to the quality, efficiency and repeatability of the process are achieved. Poor or awkward accessibility, operator fatigue, or inconsistent workmanship are eliminated. The Gullco Standard Platform (GSP) range of controls have switching for forward / neutral / reverse, run / stop, Manual / Auto & program variable increment/decrement (where applicable) and a rotary encoder for speed control. This micro-processor based, 24 volt DC motor control can be supplied to provide a variety of “optional” functions such as indexing, weld oscillation and auto-weld. The selected “option’ function and carriage travel speed/ direction are directed by a single GSP control. This ensures high levels of accuracy, quality and reliability. AUTOMATED WELDING SYSTEM KAT® 300 SERIES CARRIAGEThese carriages are the most durable, dynamic, and versatile machines available in the industry. While they are robust and feature-rich, they have been engineered to be smaller and lighter than previous models. A single carriage can perform a multitude of processes. |

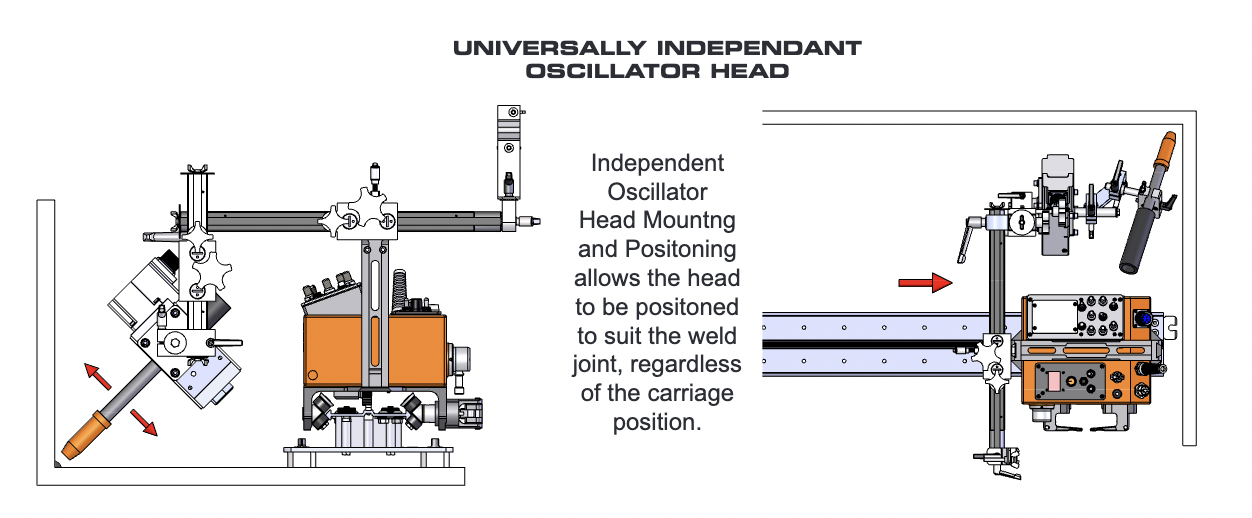

| GK-L-300 KAT® Rugged Light Weight Carriage Linear Welding Oscillation Combination Carriage Speed 1 - 32.7 IPM (2.5 - 83.1 cm/min) Heavy duty quick action self-aligning wheels combined with two track mounting paddled locks. Accurate Carriage speed control by conformal coated ingress protected 24 volt Gullco microprocessor. Maximum load capacity 56 lb (25.4 kg) regardless of weld position. With forward/stop/reverse switch, high speed return, infinitely variable multi-turn speed potentiometer and LED display. Oscillator control provides Auto Arc Start , independent dwell at each end and center of the 1.5” stroke, infinitely variable 0 to 5 seconds; oscillation speed potentiometer, speed range 8 to 188 cycles per minute (16 to 376 passes per minute). Weld oscillator head mounted on infinitely variable dovetailed tool-less racking system. |

| GK-R-300 KAT® Rugged Light Weight Carriage Radial Welding Oscillation Combination Carriage Speed 1 - 32.7 IPM (2.5 - 83.1 cm/min) Heavy duty quick action self-aligning wheels combined with two track mounting paddled locks. Accurate Carriage speed control by conformal coated ingress protected 24 volt Gullco microprocessor. Maximum load capacity 56 lb (25.4 kg) regardless of weld position. With forward/stop/reverse switch, high speed return, infinitely variable multi-turn speed potentiometer and LED display. Oscillator control provides Auto Arc Start , independent dwell at each end and center of the 0.8 - 45 ̊ oscillation width stroke, infinitely variable 0 to 5 seconds; oscillation speed potentiometer, speed range 1 ̊ - 45 ̊ per second. Weld oscillator head mounted on infinitely variable dovetailed tool-less racking system. |

RSS Feed

RSS Feed