| A welding machine can only operate continuously for a certain amount of time. It is important to monitor the temperature of the machine during use to ensure it does not overheat. For safety reasons, it is very important to be aware of the duty cycle of your machine to avoid exceeding it. Exceeding the duty cycle can cause the machine to catch fire, if the thermal overload protection fails to work. You can often find out what the duty cycle is by looking on your machine for a sticker or checking the owner's manual of the equipment. |

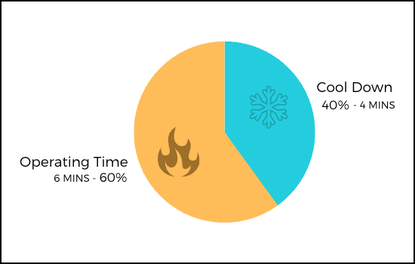

| Duty cycle is measured using a 10-minute cycle and expressed as a percentage of that 10-minute block with the remaining minutes used for cooldown. So say the duty cycle for your welding machine is 60%, this means that the machine can operate for 6 continuous minutes before it needs 4 minutes to cool down and restart. |

Other things to note: |

- Duty cycle and welding output have an inverse relationship- this means that as welding output decreases, duty cycle increases.

- The duty cycle of your machine is based on a specific ambient temperature. The average ambient temperature that industrial equipment manufacturers use is 104 F. If the ambient temperature is cooler, duty cycle increases.

- If your machine is a multi-process, multi-voltage welding system, duty cycle and welding output will vary by process and input power.

Why does Duty Cycle Matter? |

| Even though welding machines have thermal overload protection, if it does not kick in your machine can catch fire. When you know the duty cycle of your machine, then you’ll know when to stop working and let your machine cool down. Aside from staying safe, duty cycle can also impact quality. If you are always hitting or exceeding the limit of your machine's duty cycle, you can end up with poor-quality welds. You may be welding a part, when your machine suddenly shuts off midway! Keeping the duty cycle fresh on your mind while working can prevent this. Stay safe and achieve the quality welds you want! |

RSS Feed

RSS Feed