|

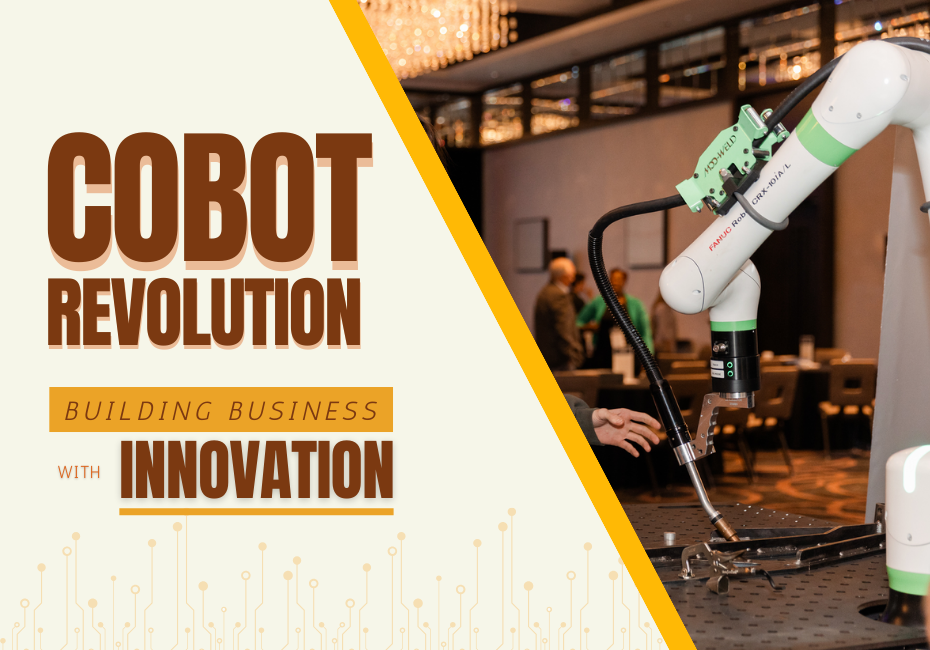

The future is now! Diverse manufacturing sectors, from automotive to electronics, are embracing collaborative robots or cobots for a variety of tasks. This partnership blends human expertise with cobot precision, helping to achieve consistent quality results, increase response time or meet market demand. Whether for consistency or efficiency, cobots are pivotal in advancing manufacturing. Let's talk about what they could do for you!

The number of industrial robots sold between 2017-2021 grew from 381k to 630k, a 13% annual growth rate*. As we enter 2024, these numbers are only just increasing. Because cobots are collaborative robots that work alongside your staff to complement their skills, your company is able to increase the output while keep labor costs low. Saving money on your bottom line will offer you that competitive edge to stay ahead in your industry!

*International Federation of Robots, World Robotics 2018

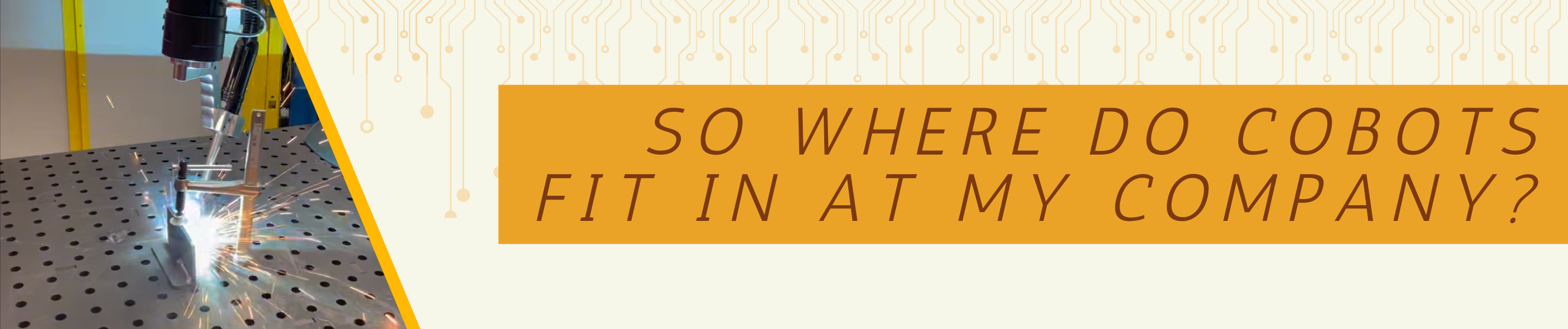

Well, the great thing about cobots is that they can do many of the tasks that humans are capable of but dislike or are put in unnecessary danger while performing. Cobots can also take over monotonus or repetitive tasks on your production line that may have a higher rate of error if a human was to do them. So it's not about what the cobot can do that you can't, it's about how a robot can partner with your team to increase speed, efficiency, and accuracy.

Cobots are an extraordinarily flexible asset- they can be free standing moveable machines that are customizable and reprogrammable. So while your human team brings dexterity, creativity, reasoning, and critical thinking to the table, a welding cobot can help them achieve in areas that require accuracy, flexibility, speed, strength and repeatability! Investing in cobots offers a range of strategic advantages for businesses. These versatile automation tools enable companies to attain consistency in both quality and quantity, contributing to enhanced overall production output. They are particularly valuable in filling employment gaps during upswings and seasonal requirements, ensuring that manufacturing capability can grow seamlessly. Their implementation allows for increased response time to consumer needs, meeting the market demand for customization. Moreover, cobots address the persistent shortage of skilled manufacturing workers, leading to productivity gains, the ability to scale your operations and a reduction in operating costs. Embracing cobot technology is a solution that fosters efficiency and competitiveness in the dynamic landscape of modern manufacturing!

Cobots are used in all sorts of industries- think metal fab, automotive, electrical/electronics, plastic and chemical products, food and beverage, and much more.

Common uses for cobots include:

There's no one fits all cobot solution for every company. Check out these tips for help choosing what process to automate and how to ensure automation success for your staff & your bottom line! If you are interested in seeing what a welding cobot package could do for you, fill out our inquiry form to receive a sample weldment and see firsthand how automation can improve your process and increase your parts production! And if you're still struggling, our team is happy to help you figure out a solution that best fits your needs- just fill out the form below or reach out by phone today! |

- Products & Services

- Gases

-

Welder Training

-

Program Overview

>

- Pricing and Class Schedule

- How to Register

- Tour Our Facility

- Why Earlbeck Technical Center

- On Site Training

-

Frequently Asked Questions

>

- Are student loans, financial aid, or scholarships available?

- How long does it take to complete the program?

- What should I bring for my first day of class?

- Where can I find information about weather related closures or delays?

- Do you offer job placement?

- How Much Money does a Welder Make?

- What is the Job Outlook for Welders?

-

Program Overview

>

-

Weld Testing

- Welding 101 Blog

- Locations & Contacts

- More...

Baltimore, MD8204 Pulaski Hwy

Baltimore, MD 21237 Welding Supply & Gas Showroom Hours: Mon- Fri 7:30 AM - 5PM Phone: (410) 687-8400 Fax: (410) 687-1394 Welder Training & Testing Center Phone: (410) 687-8400 |

Beltsville, MD10792 Tucker St

Beltsville, MD 20705 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (301) 937-8884 Fax: (301) 937-1811 6170 Hughesville Station Place

Hughesville, MD 20637 Welder Training & Testing Center Phone: (410) 687-8400 |

York, PA95 Aberdeen Rd

York, PA 17406 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 4:30PM Phone: (717) 916-6611 Fax: (717) 764-1281 Welder Training & Testing Center Phone: (410) 687-8400 AACC Clauson Center for Innovation and Skilled Trades101 College Parkway

Arnold, MD 21012 Welder Training & Testing Center Phone: (410) 687-8400 |

Scranton, PA4961 Birney Ave

Scranton, PA 18507 Welding Supply & Gas Showroom Hours: Mon-Fri 7:30AM - 5:00PM Phone: (570) 457-8954 3427 N Main Ave

Scranton, PA 18508 Welder Training & Testing Center Phone: (410) 687-8400 |

RSS Feed

RSS Feed